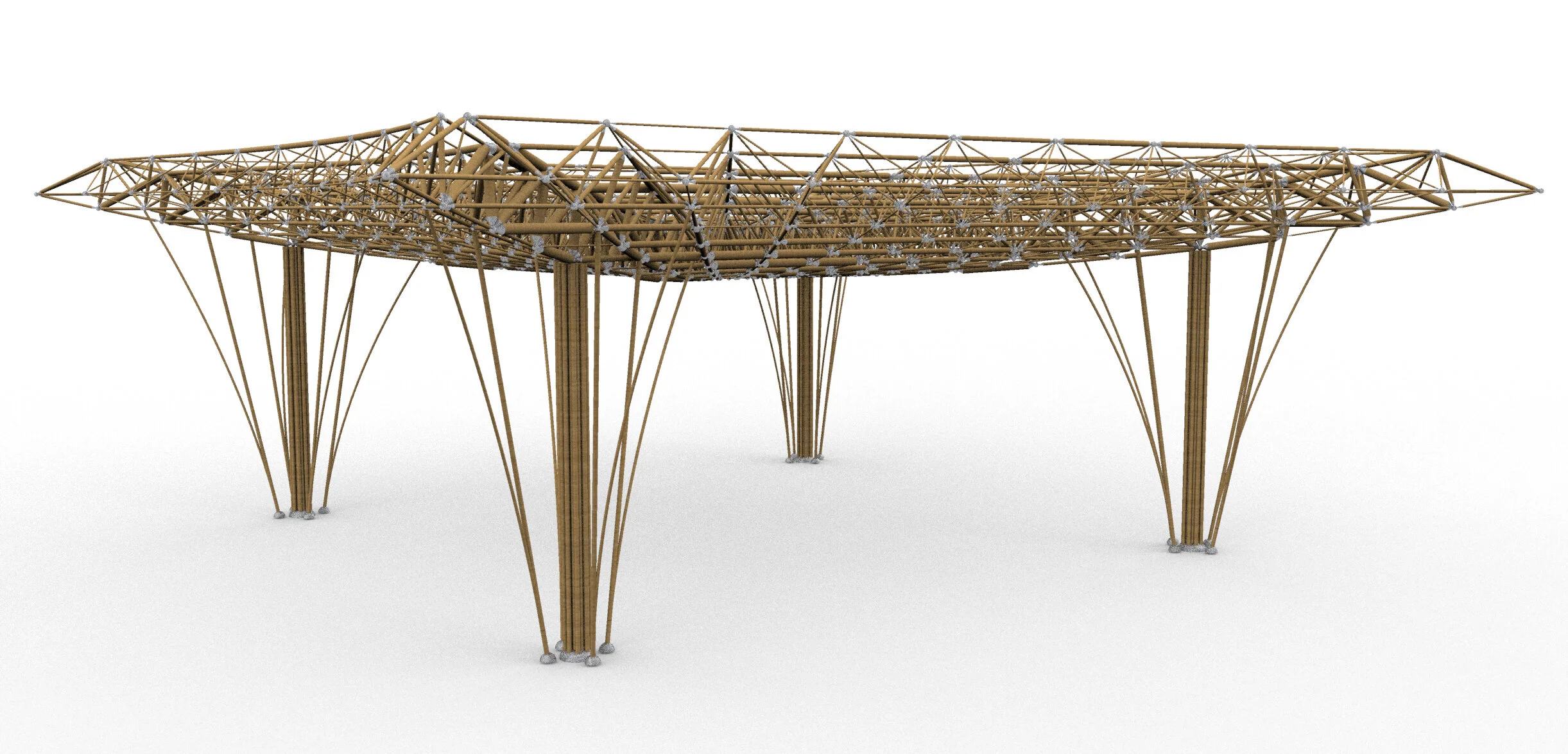

Bamboo Pavilion

This bamboo pavilion is my take on creating an eco conscious structure for a tropical environment

In Spring 2020, I took a class called Intro to Structural Design, and as a final project students were tasked with creating a long spanning roof structure; students determined its purpose. The requirements were:

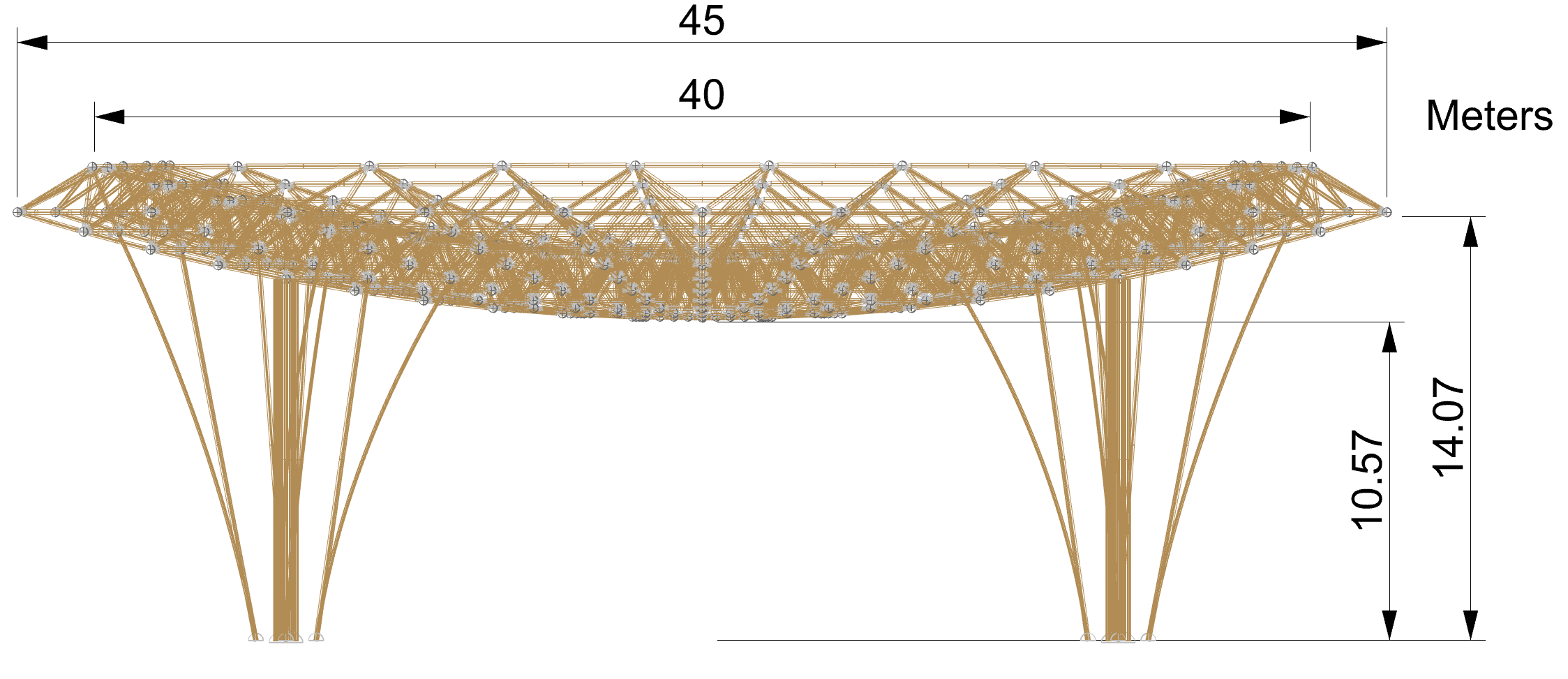

Minimum clearance of 10 meters

Minimum of 30 meters between supporting columns

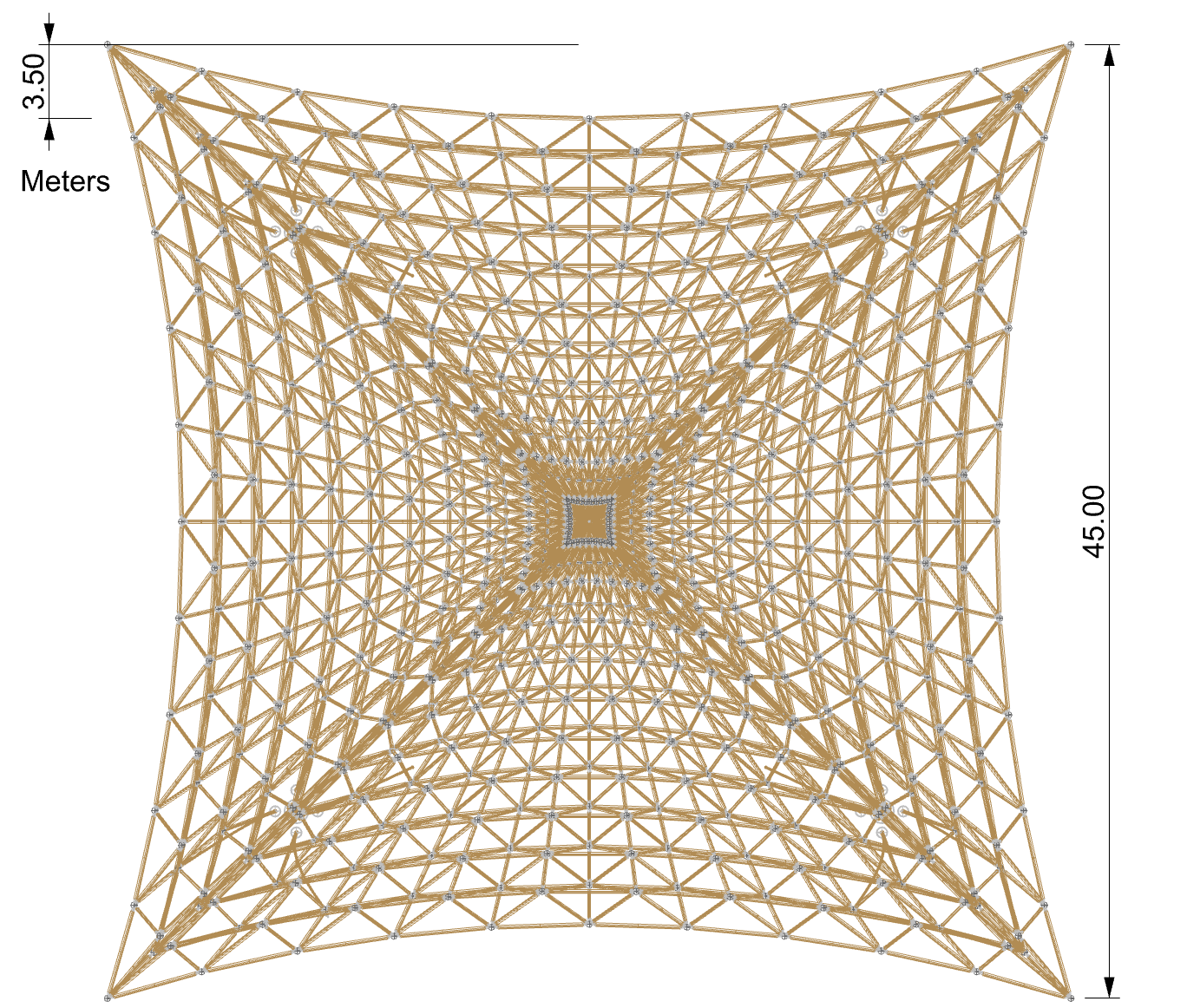

~2000 square meters of shaded area

I decided to create a bamboo pavilion because I found bamboo as a very powerful material that has good strength values while having low embodied carbon and low embodied energy CO2 environmental.

Project Members

Nebyu Haile

Programs + Tools used

Rhinoceros 3D

Grasshopper

Lunchbox - Truss Making Plugin for Grasshopper

Karamba - Structural Analysis Plugin for Grasshopper

Ideation

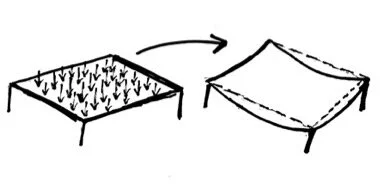

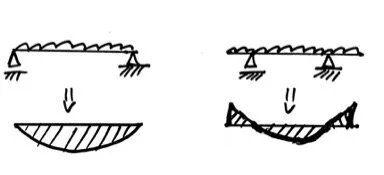

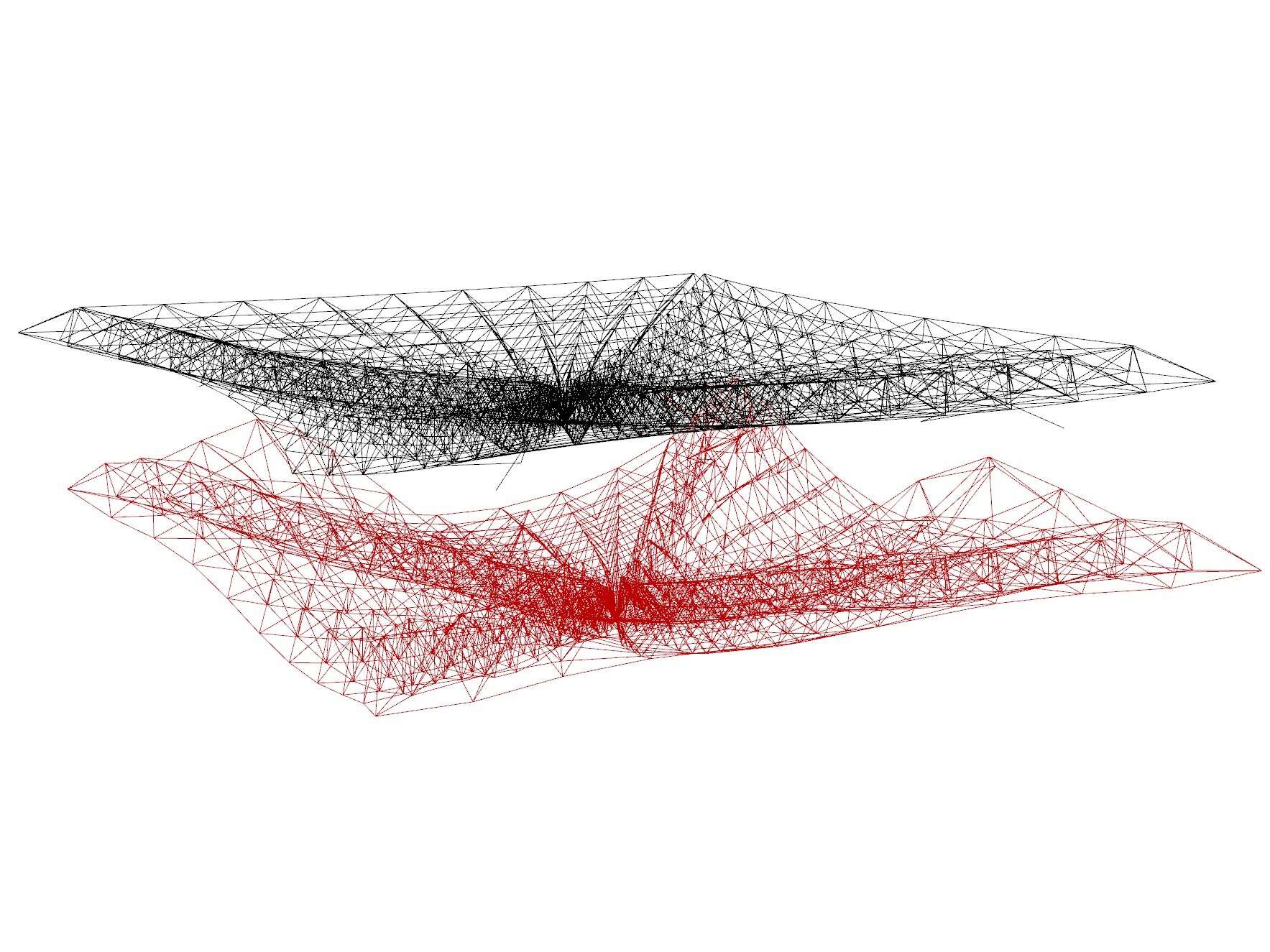

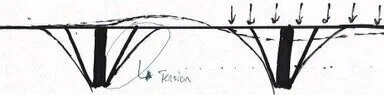

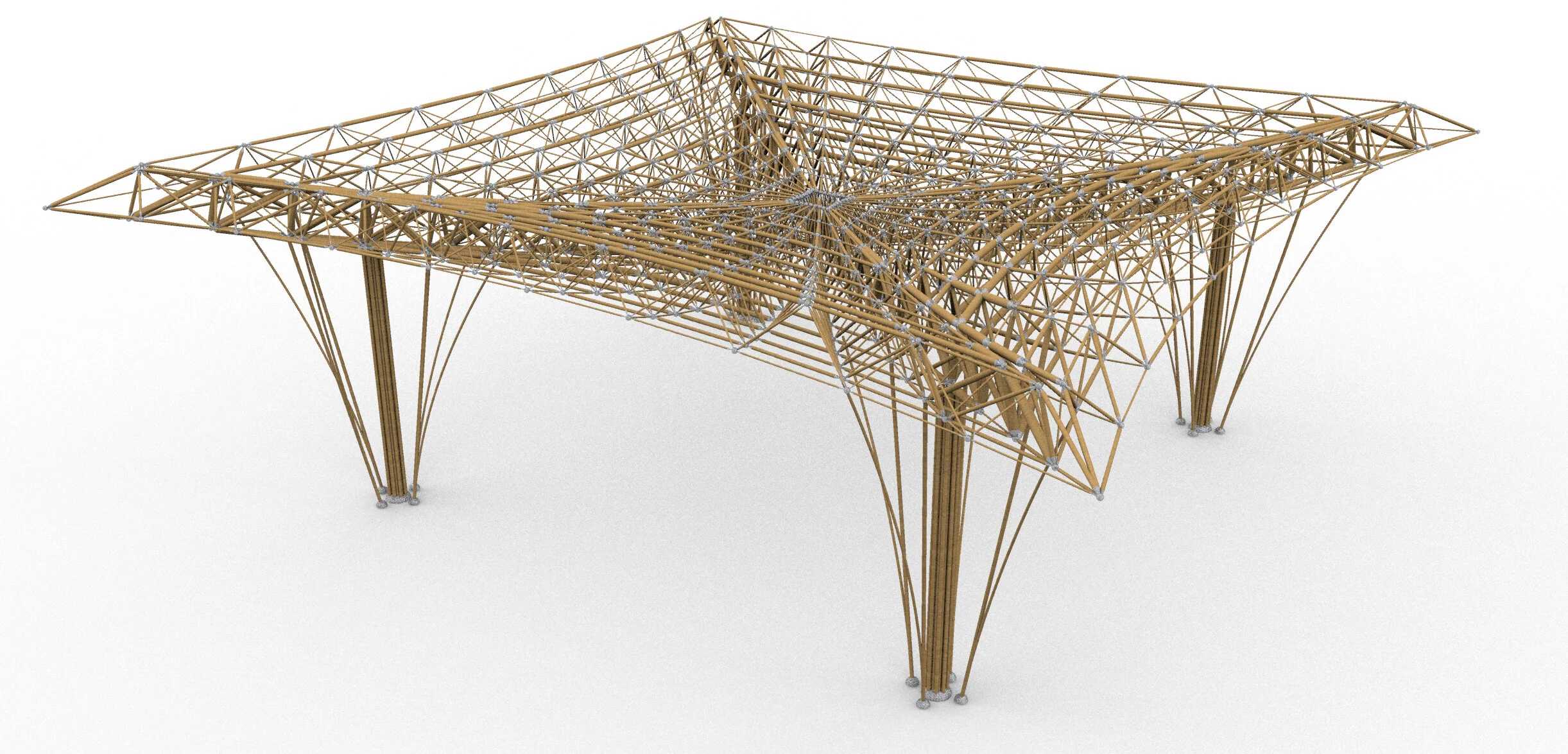

During the semester we spent a lot of time talking about how form and forces are intertwined. As a result I wanted the shape and design profile of my structure to express the forces flowing through it. As a result I spent a lot of time investigating the bending moments of flat slabs and the effects of cantilevering edges on a structure. Furthermore I looked at a lot of work by Colombian Architect Simone Velez who does lots of work with bamboo.

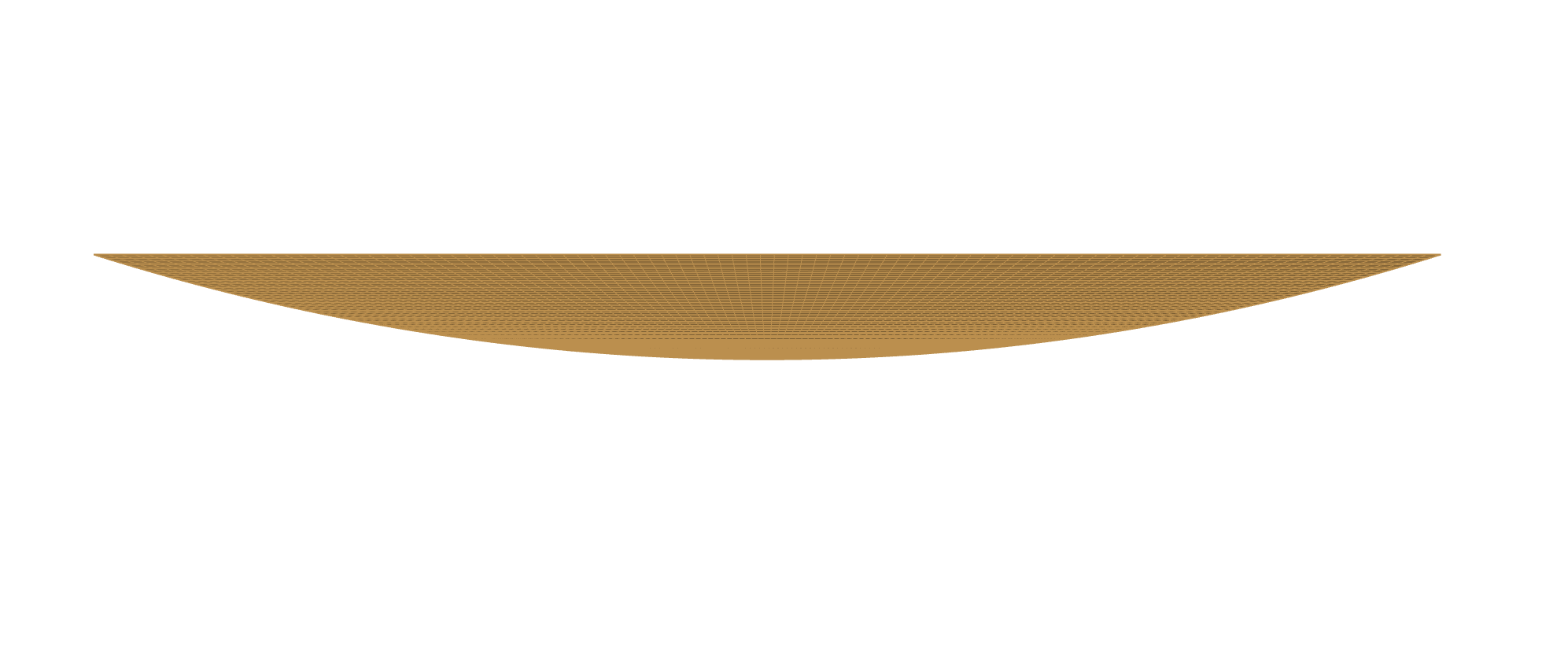

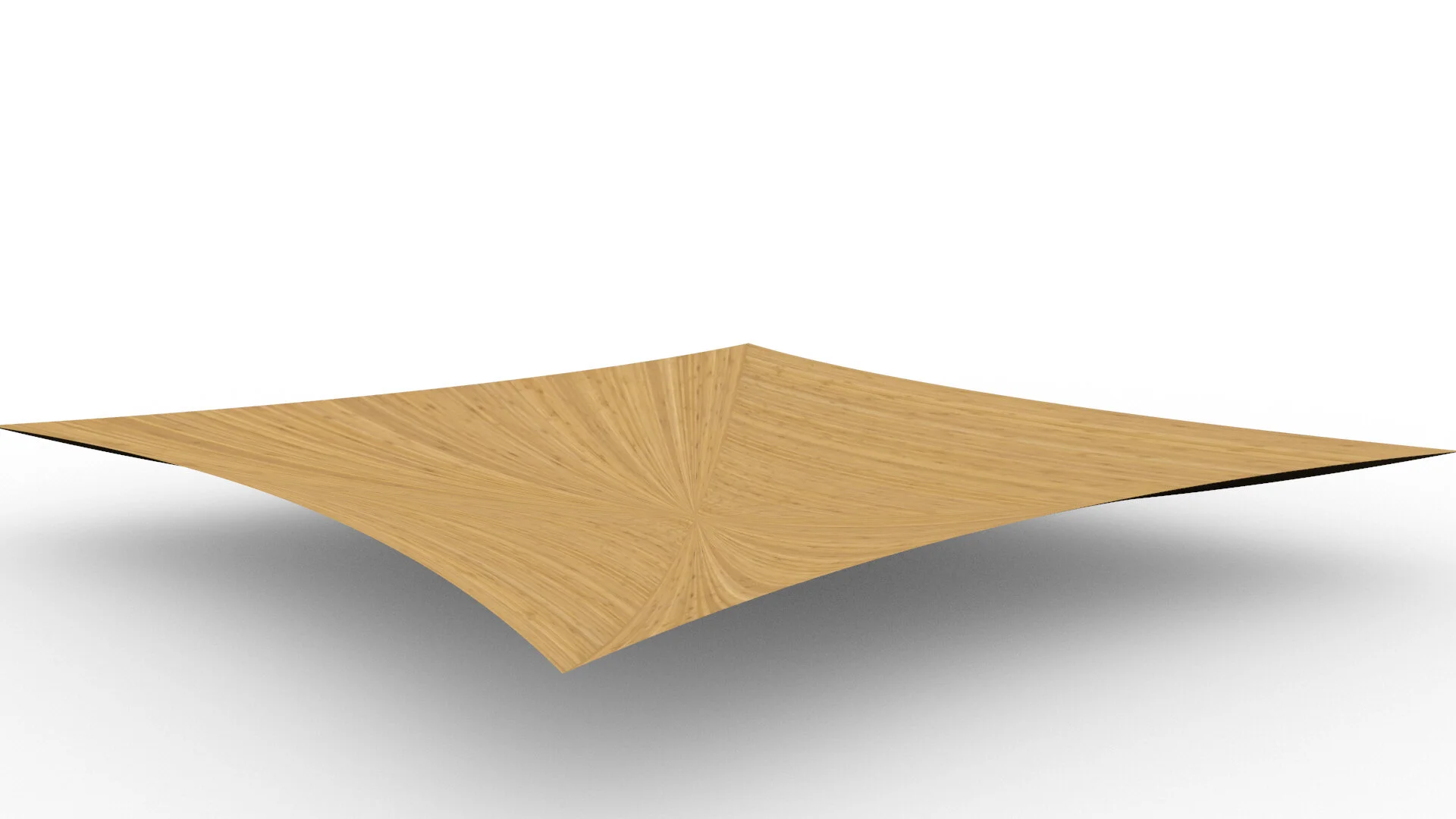

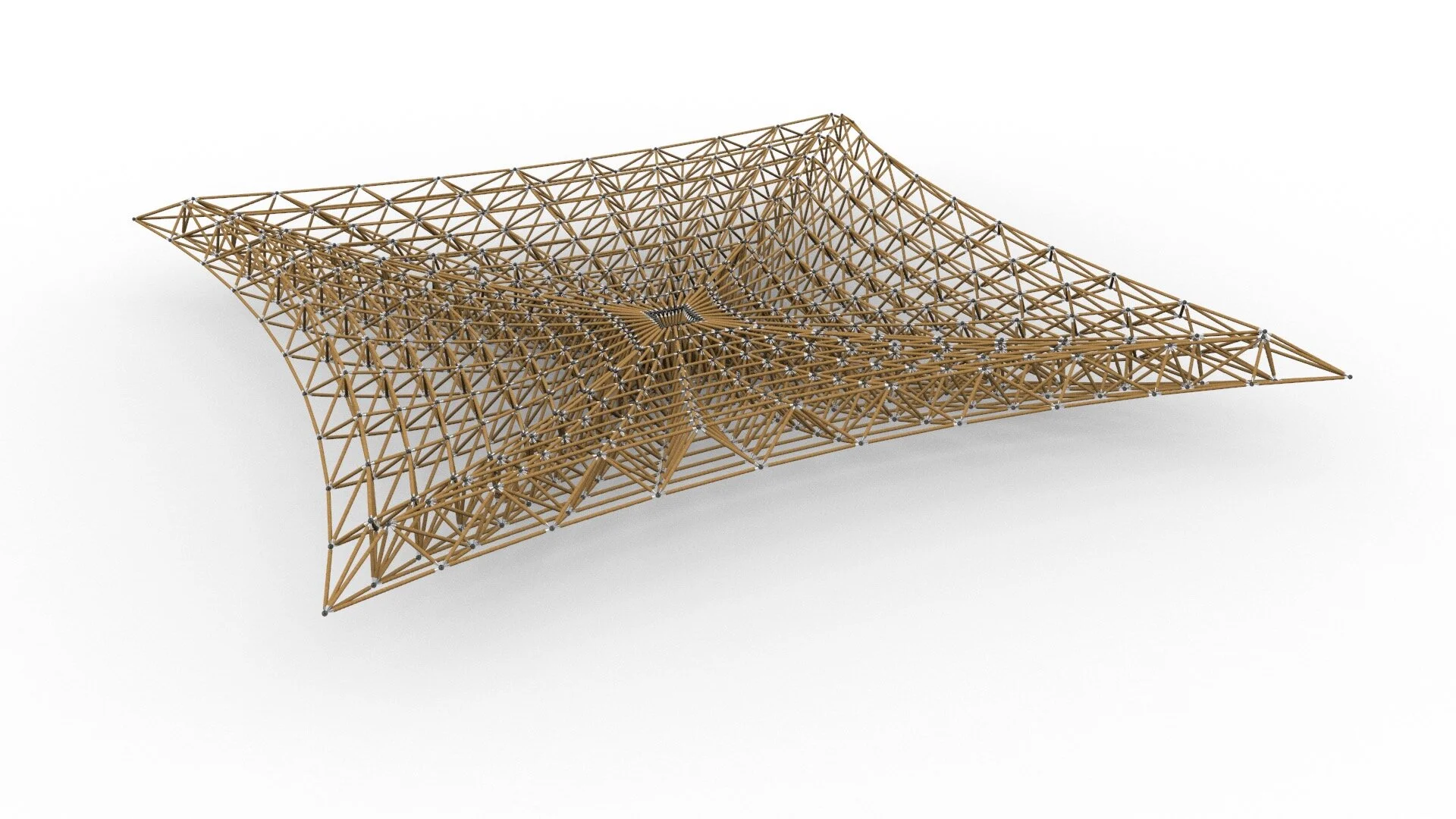

Designing The Roof

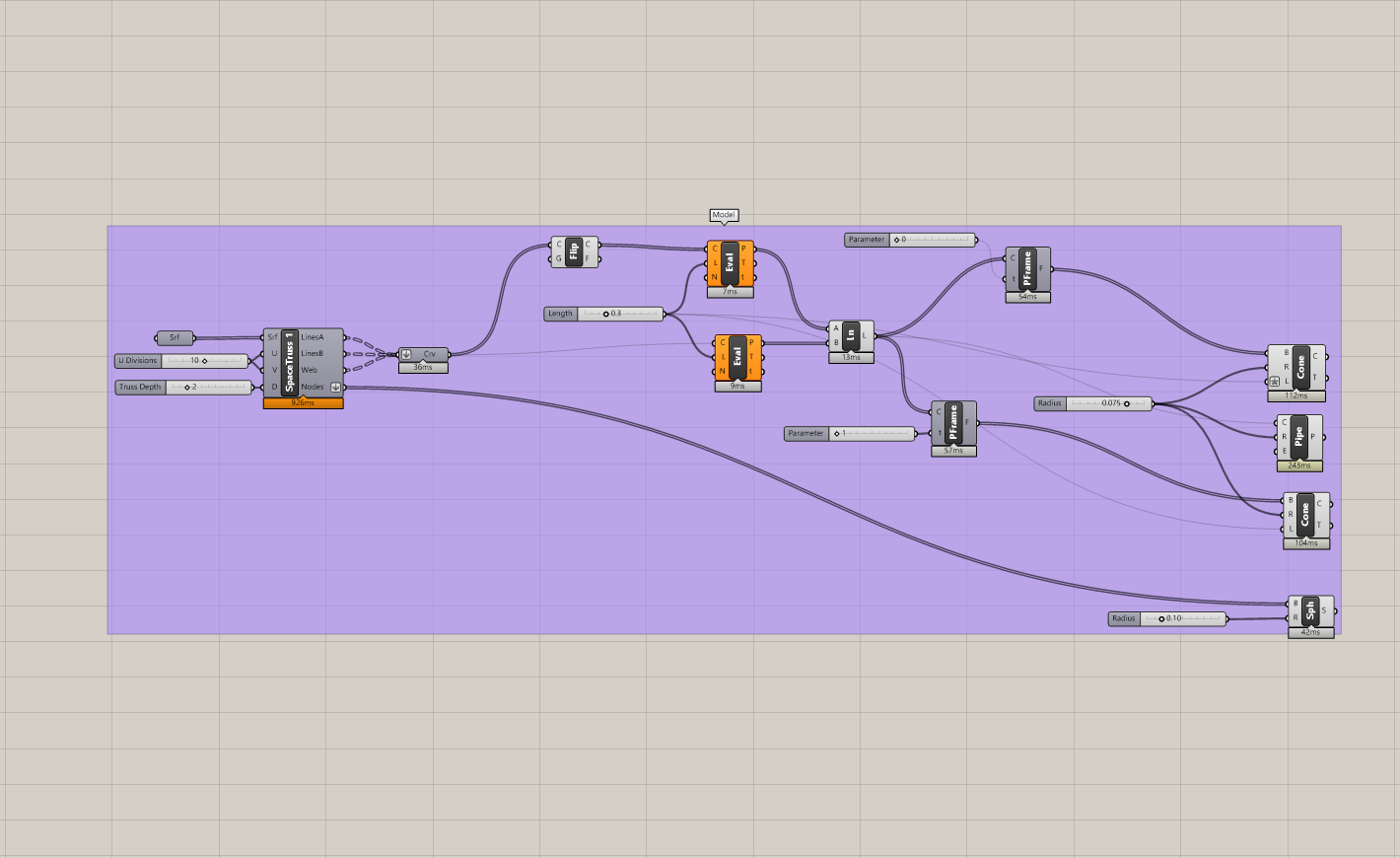

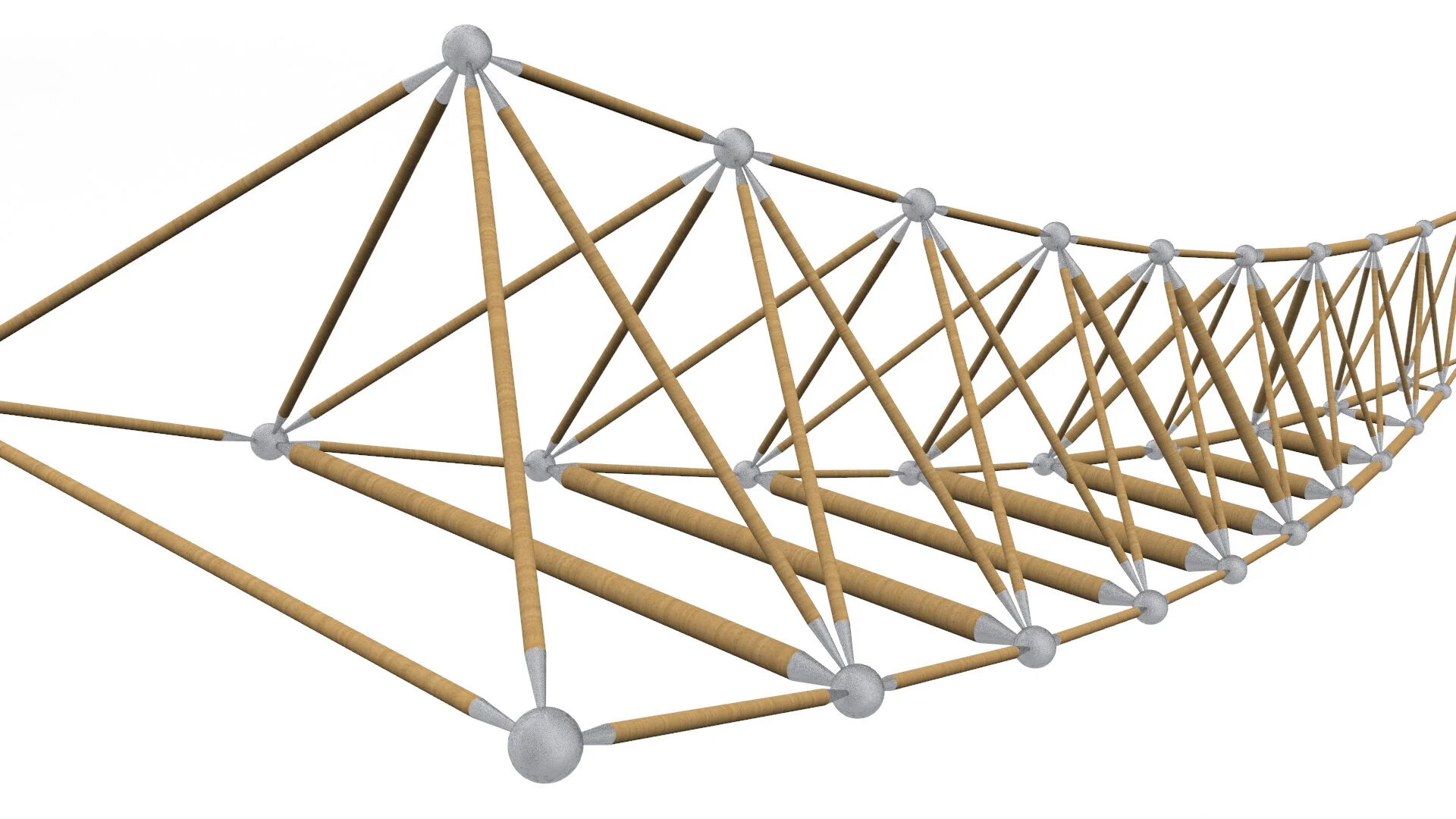

Once I had an idea for the general profile of the roof I drafted it in Rhinoceros. I debated making a solid roof, but decided on making my roof a space frame because it made it more environmentally efficient. With this decision made, I used rule of thumbs and the Lunchbox plugin in grasshopper to come up with a space frame geometry for the shape I wanted

Calculating The Forces

+

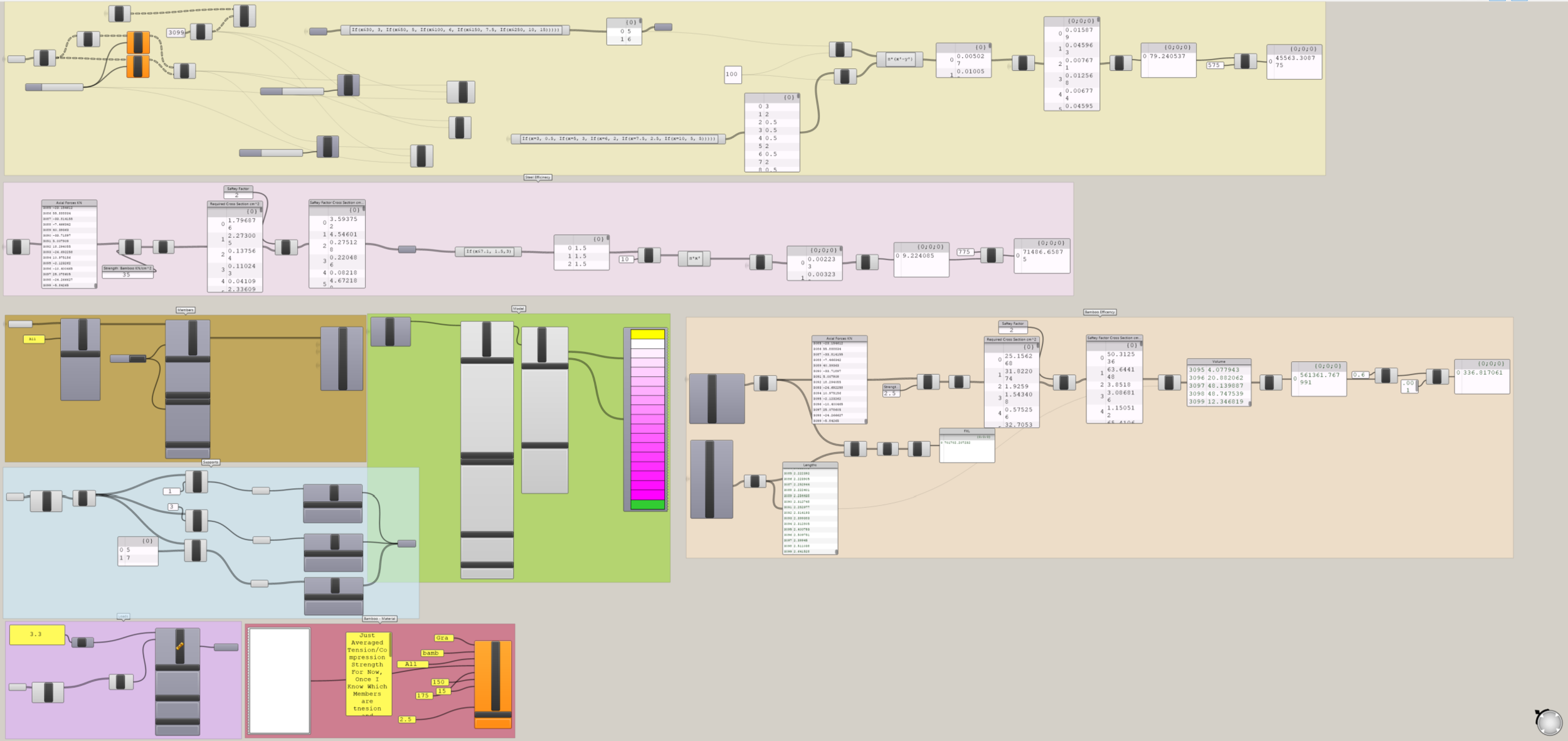

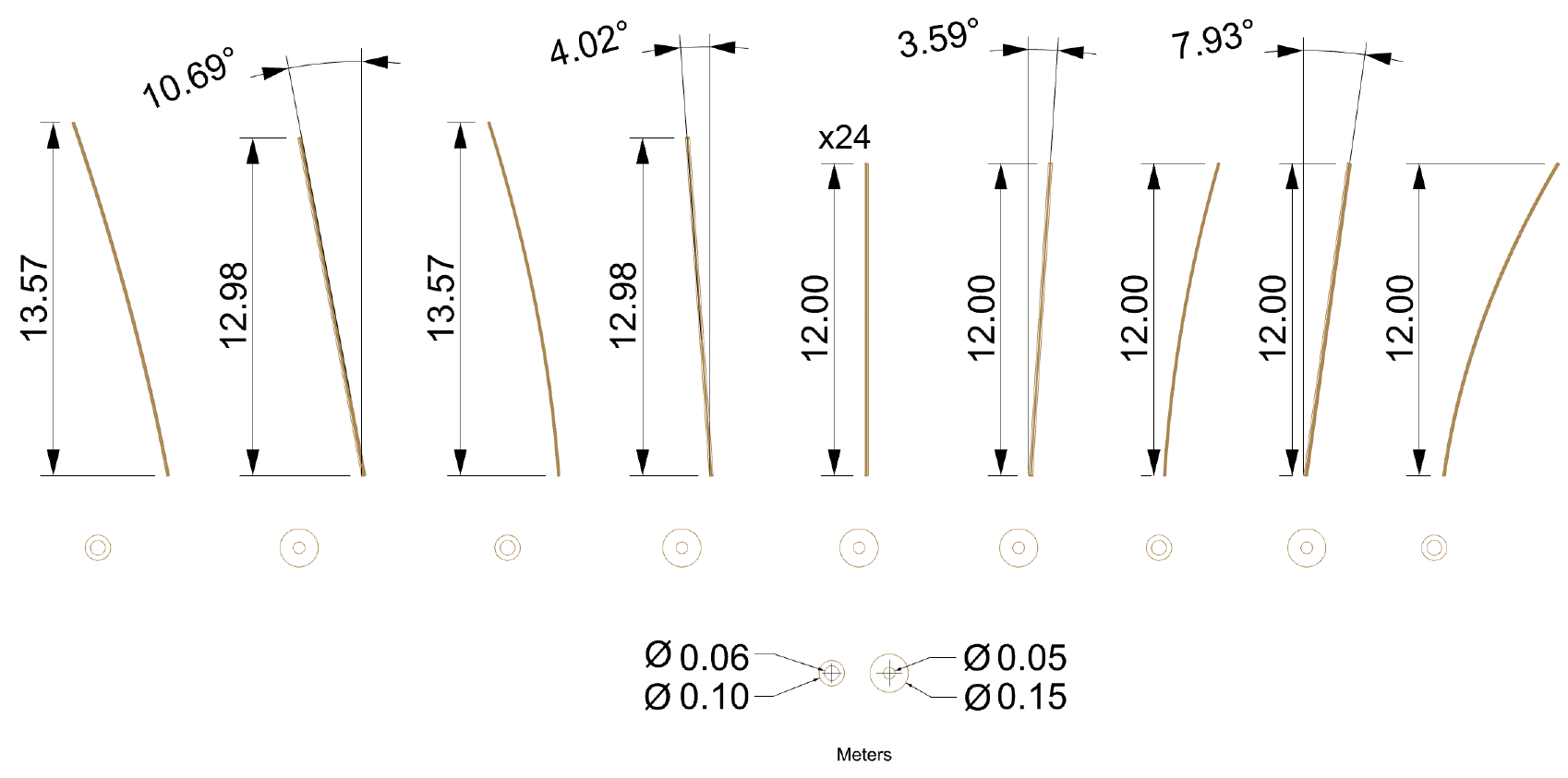

Sizing Space Frame Members

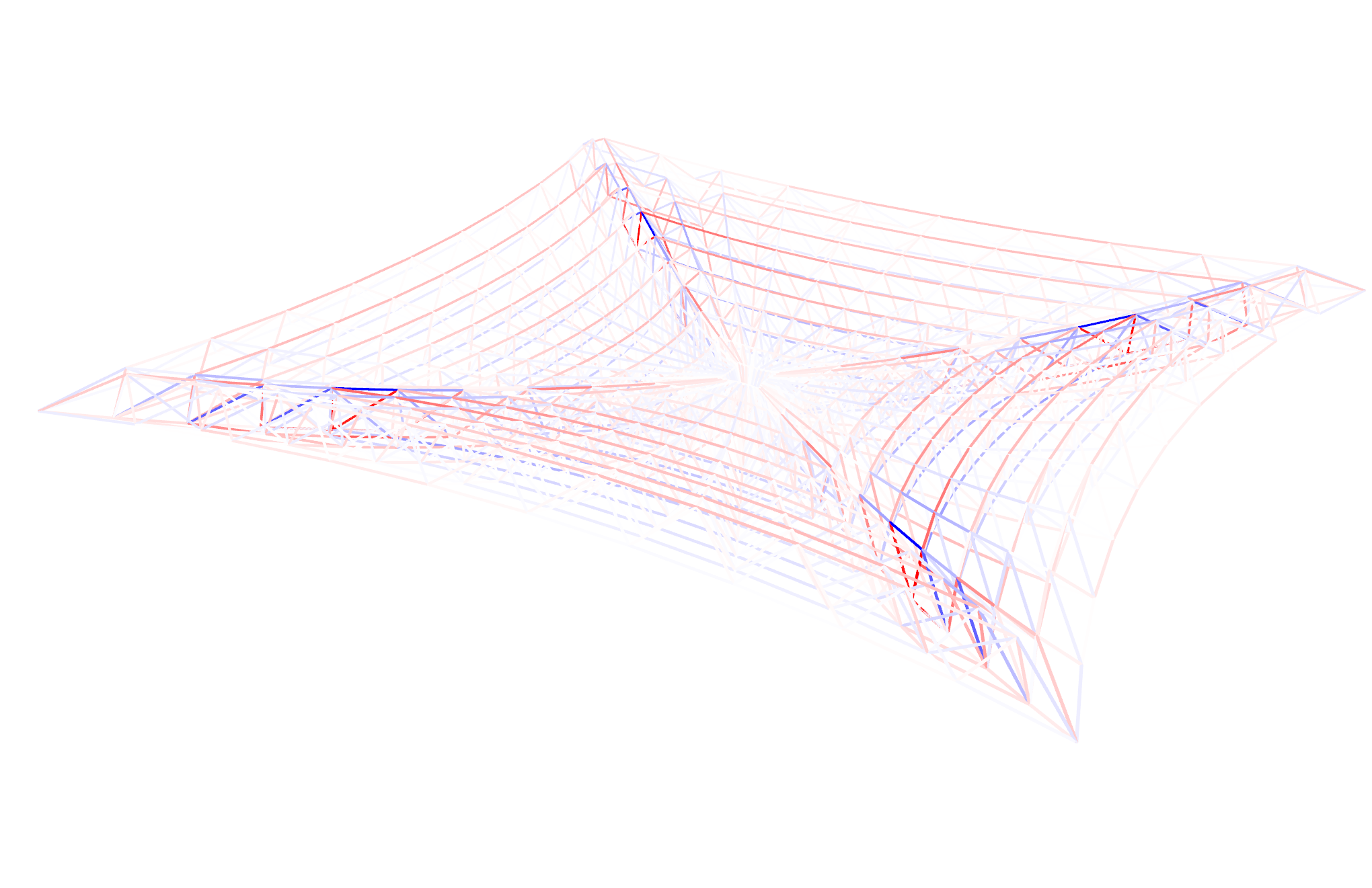

With the structure of the space frame completed, I switched over to the Karamba plugin in grasshopper to analyze structural aspects of the design such as axial forces in members, deflection of the structure and its elements, and moments. Looking at these values, I varied the support positions (collumn locations) to see how different cantilever length for the structure affected the forces in the structure.

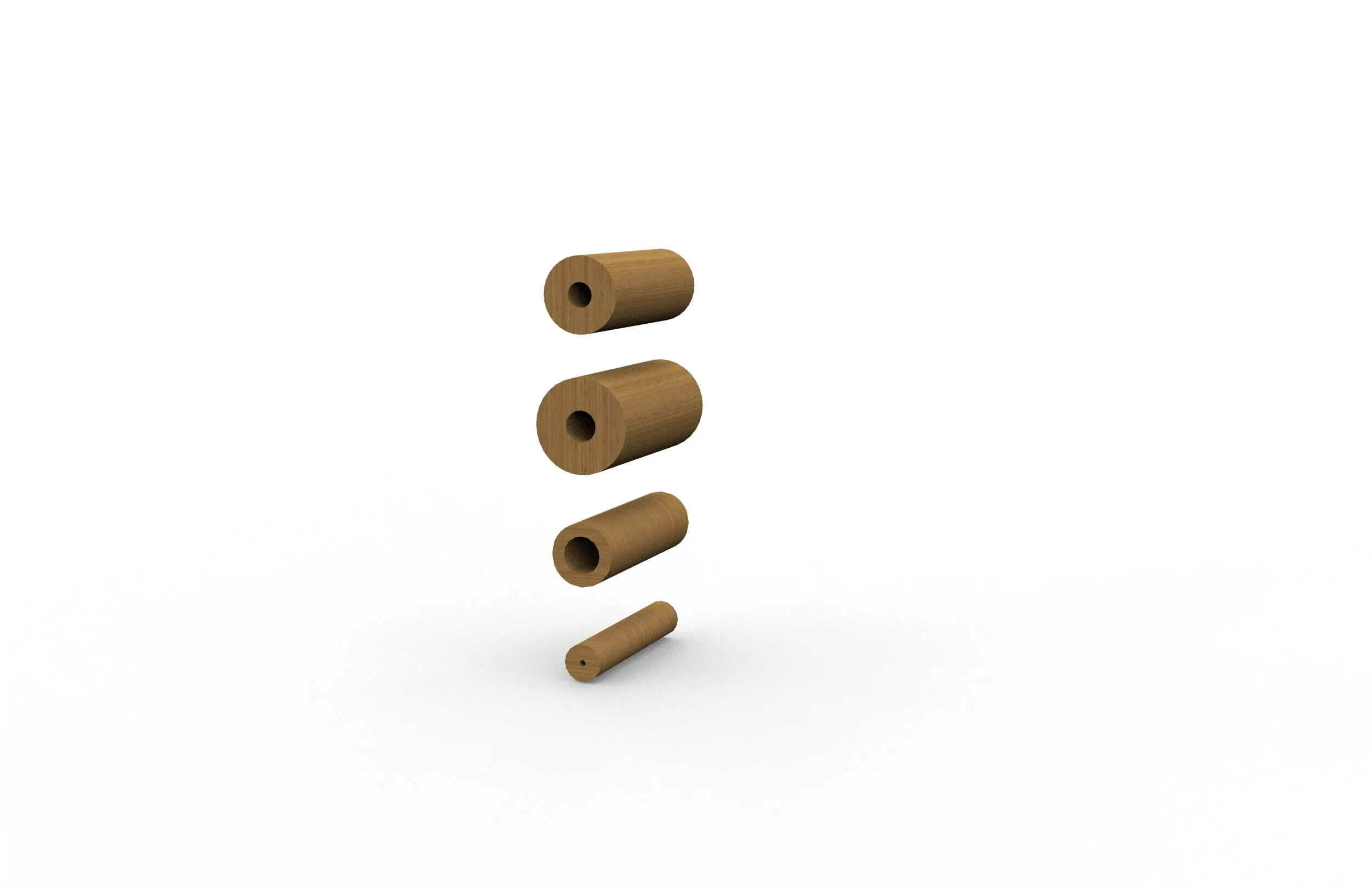

After analyzing the numbers I decided on a cantilever length for the structure, and by analyzing the axial forces in the space frame members I was able to find 4 different sizes of guadua bamboo that be used varying through the structure based on corresponding forces. Varying member size not only help express the structure/forces in the design, but it also helps reduce cost and embodied carbon over using one standardized member size.

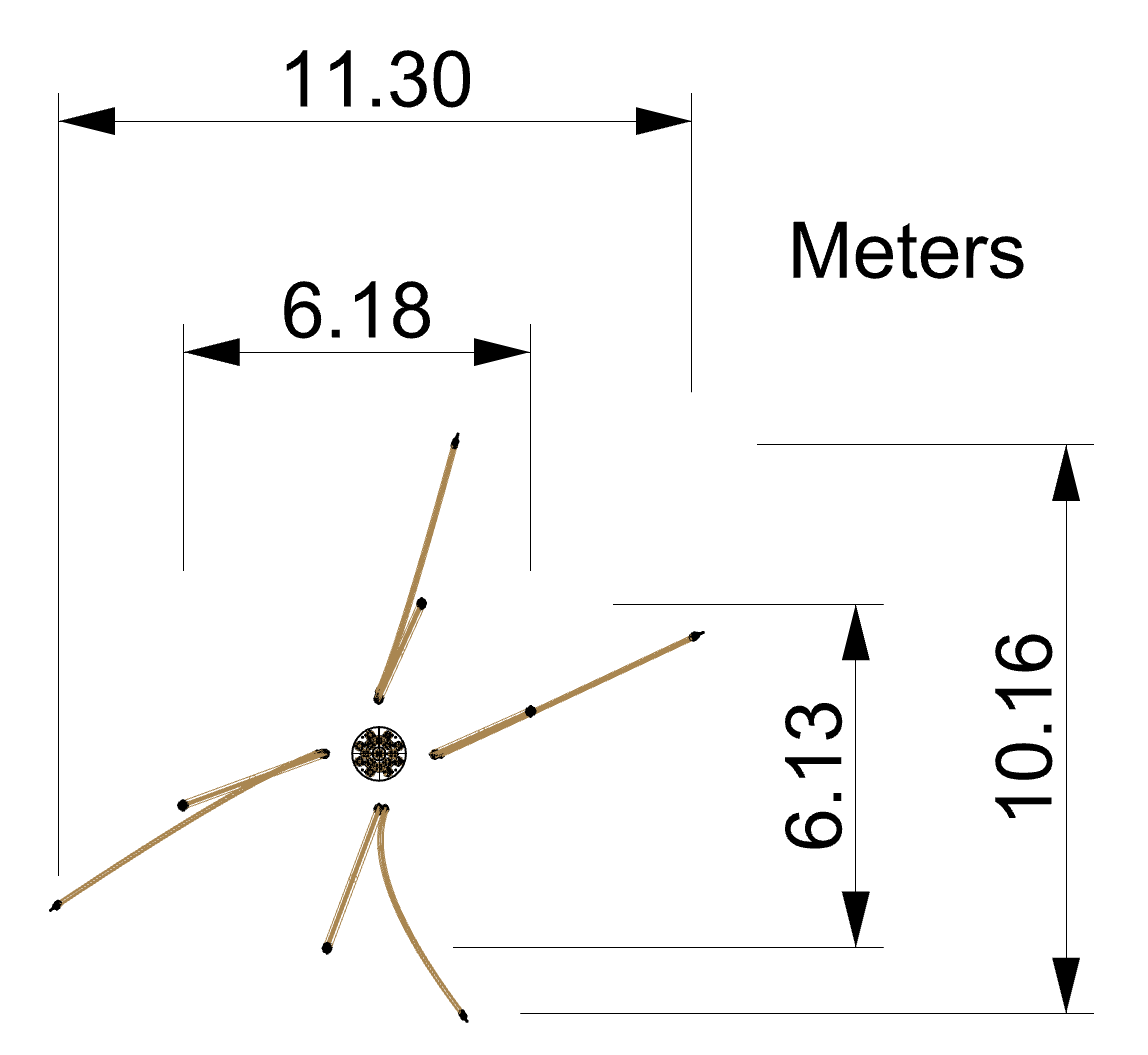

Designing The Columns

With the space frame done, I moved to designing the columns for the structure taking into account topics such as maximum compressive force of the bamboo, buckling loads, and asymmetrical load cases. The aesthetic design was focusing on making the columns look natural, in this case like a bamboo tree.

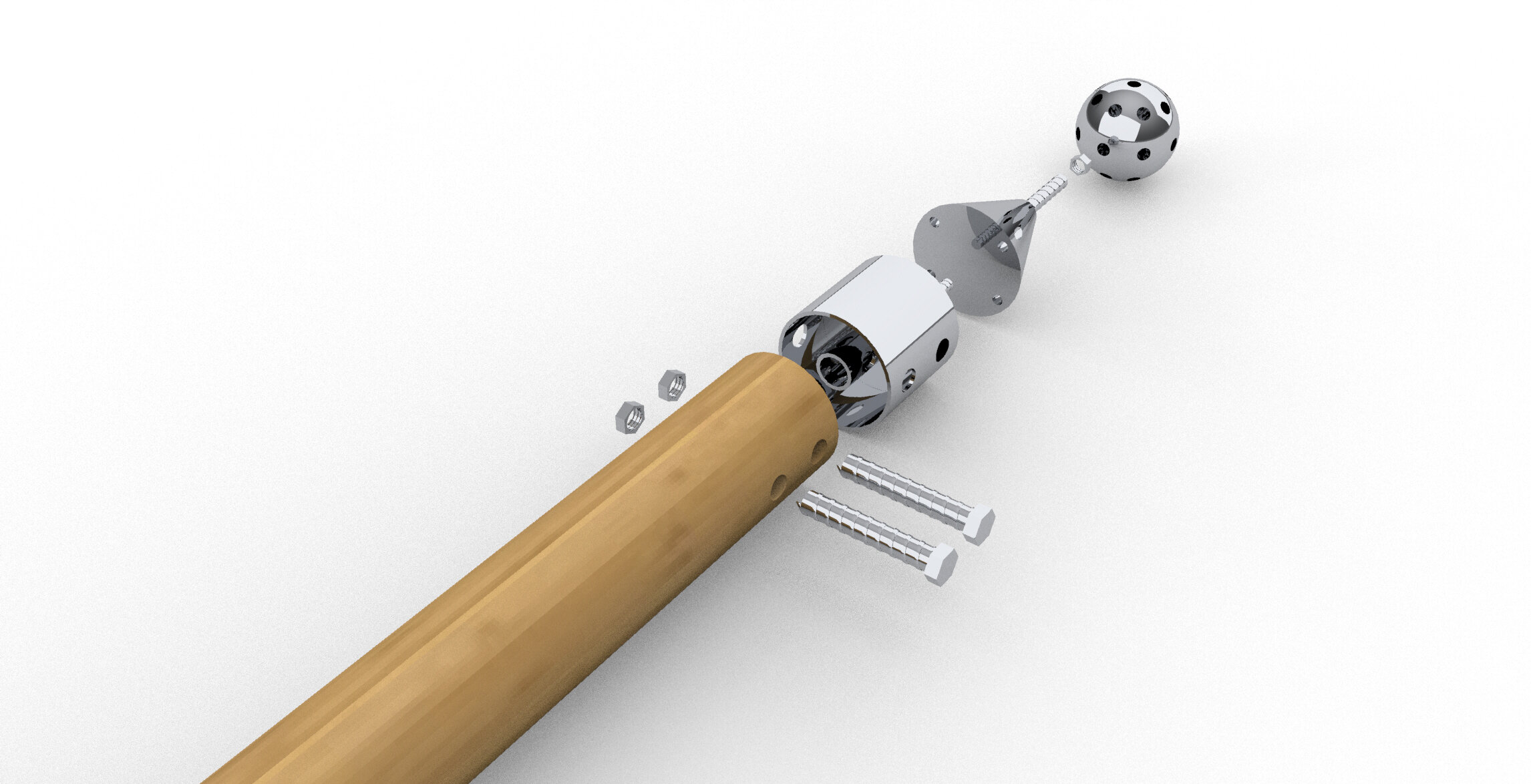

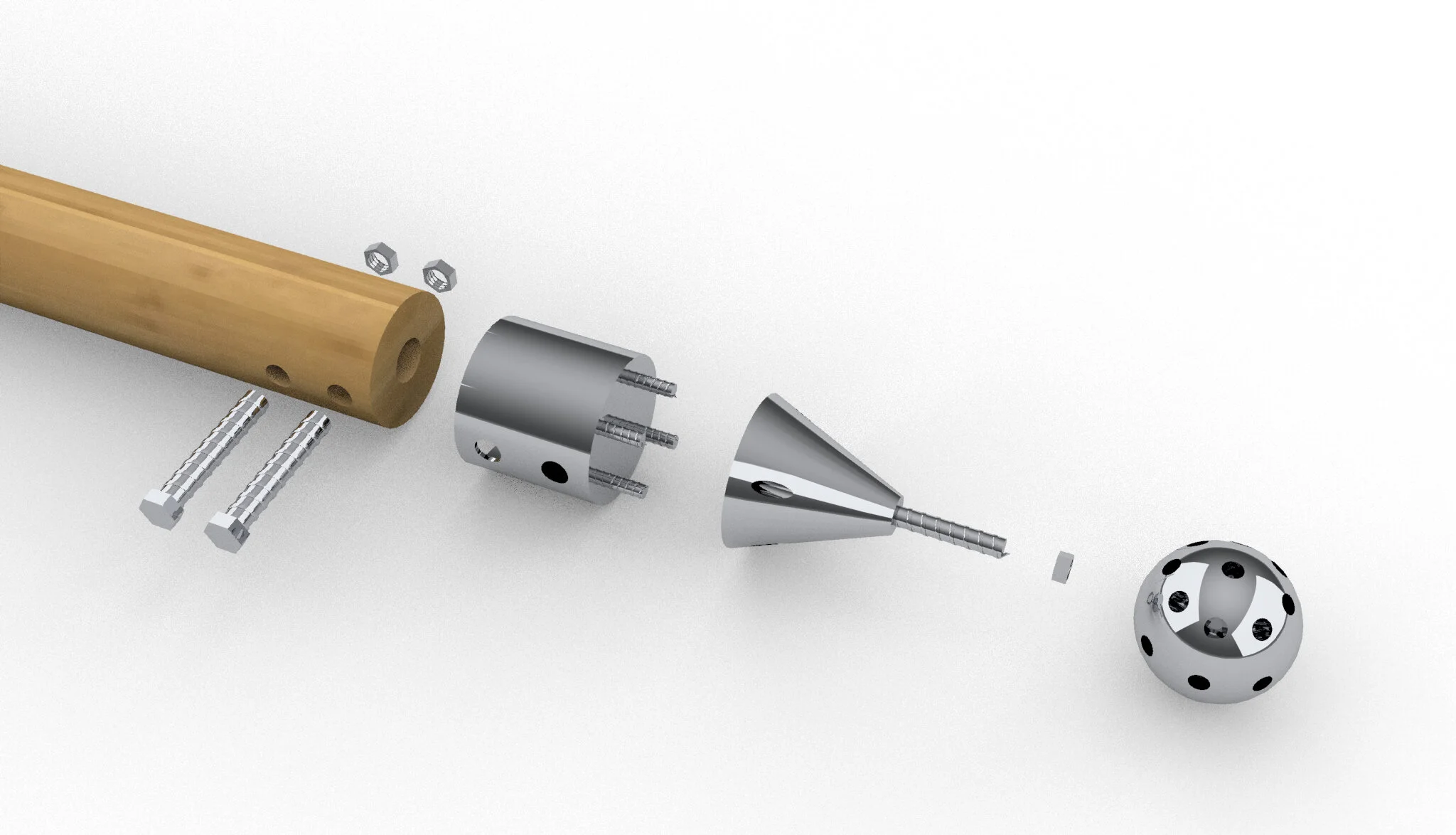

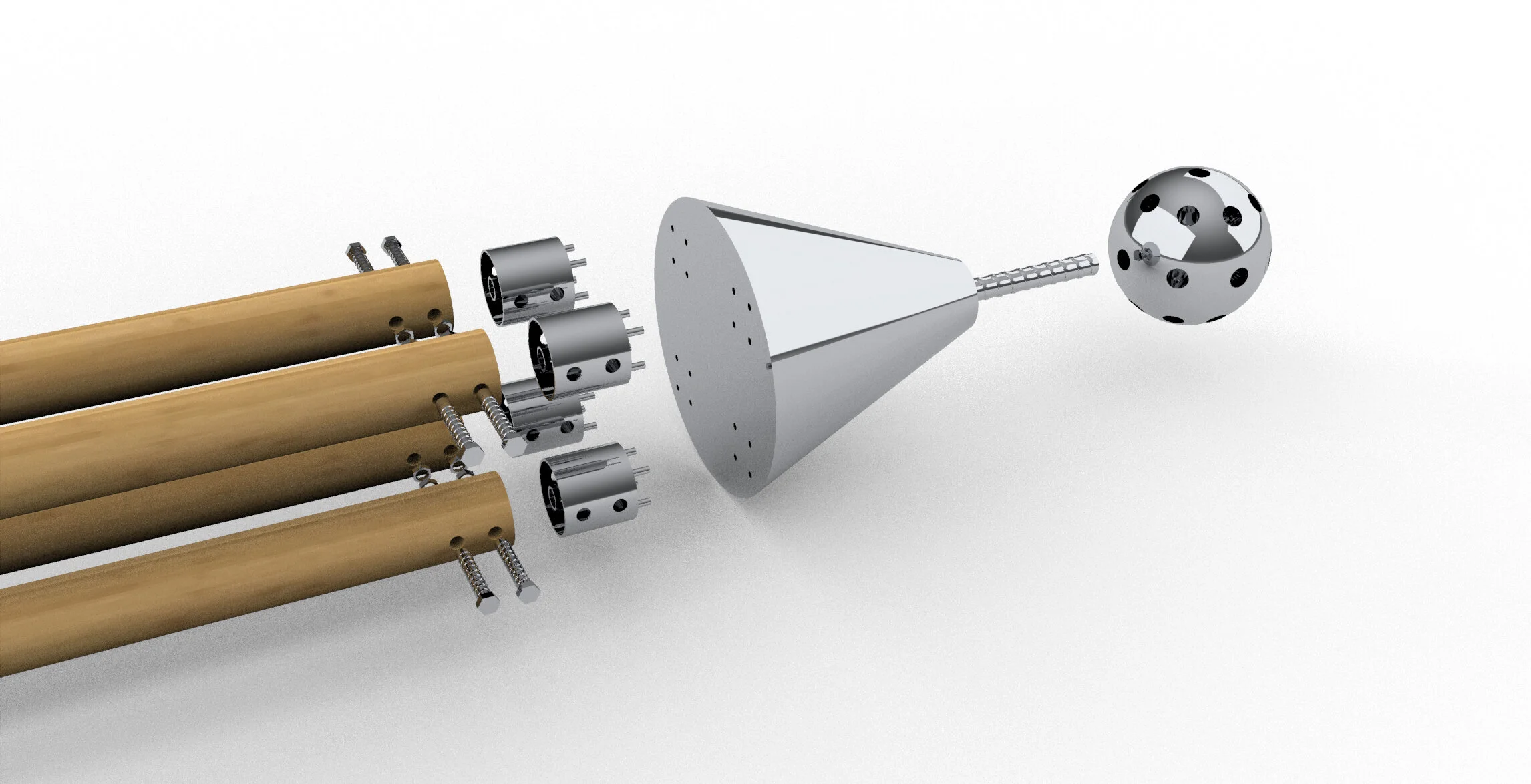

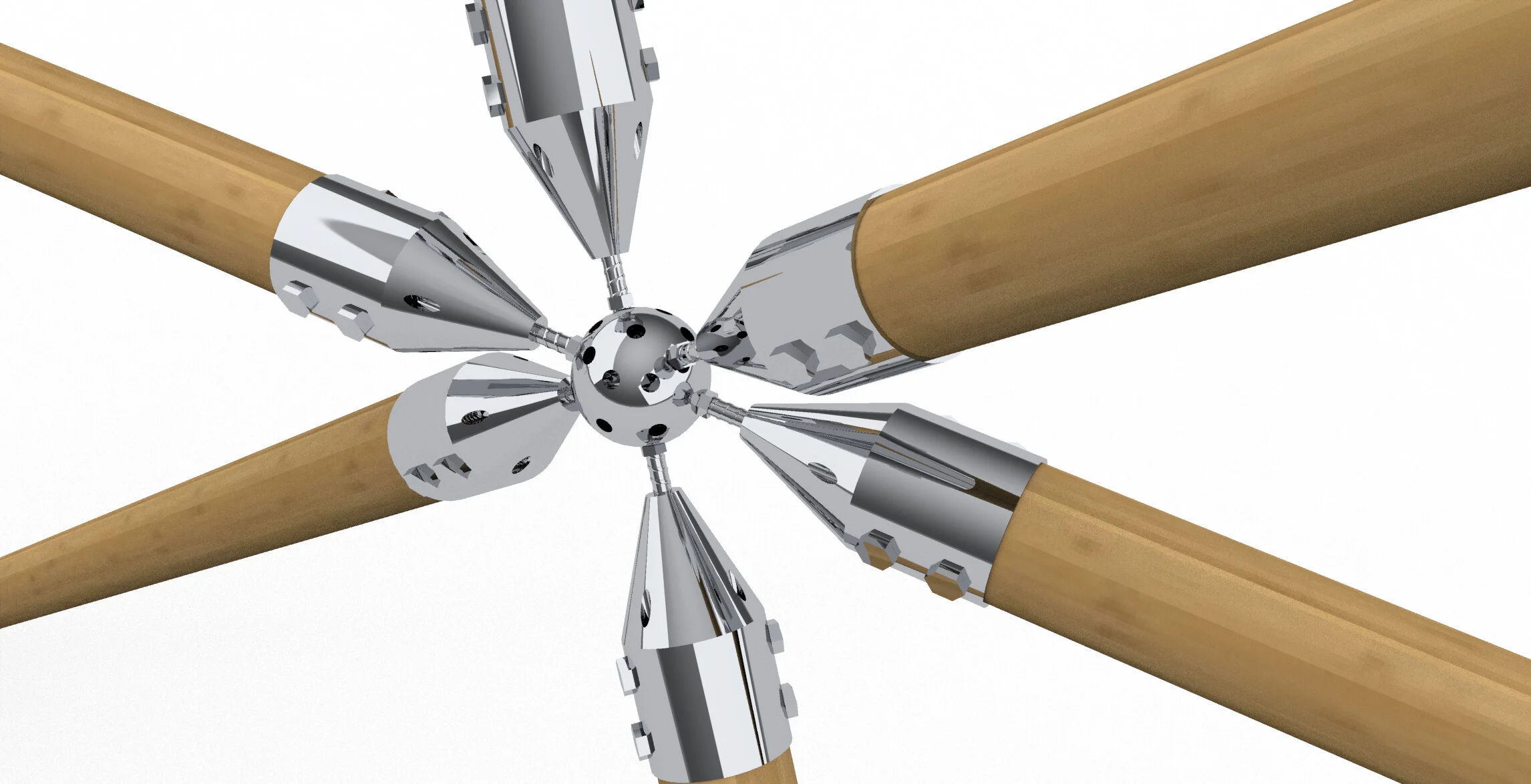

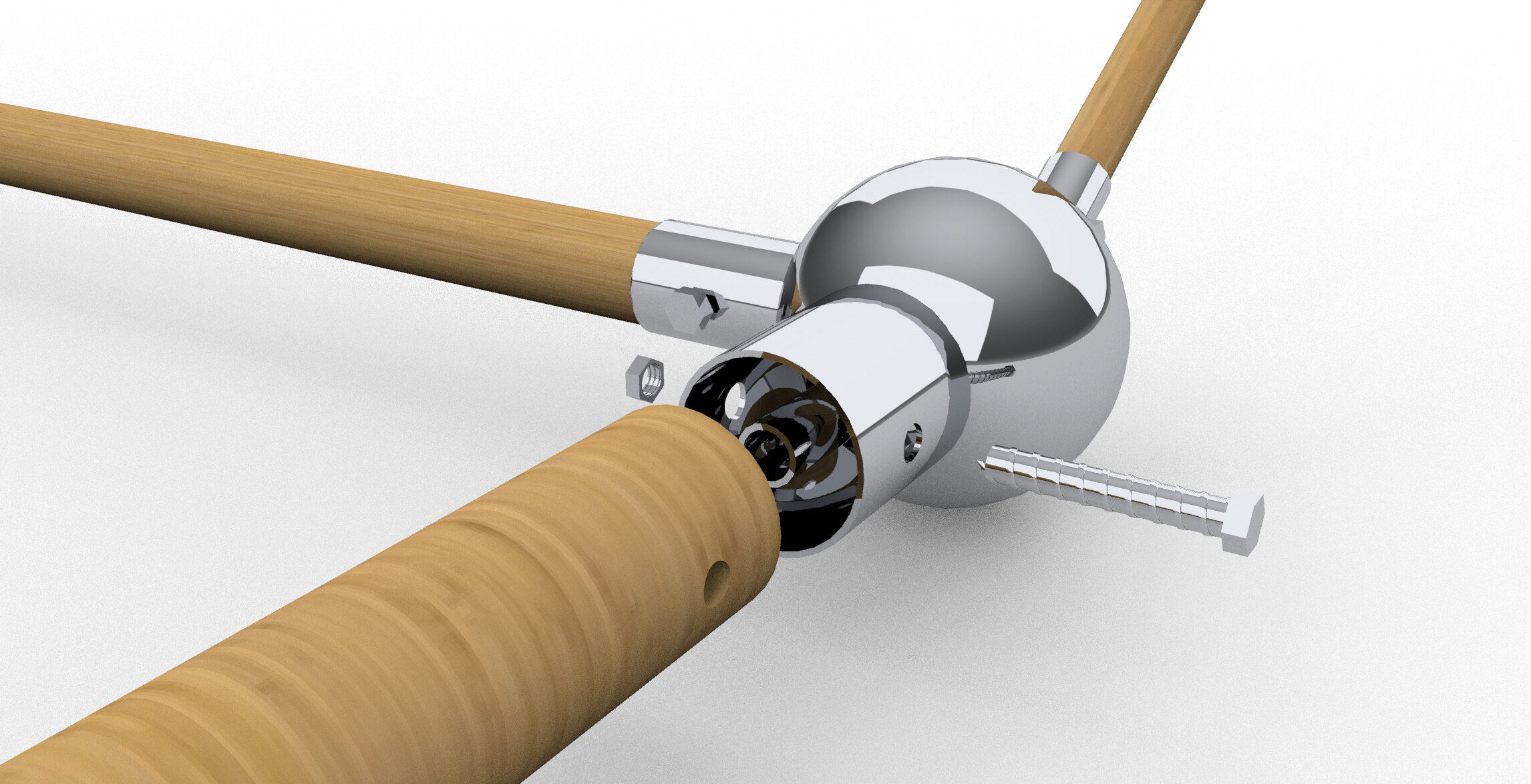

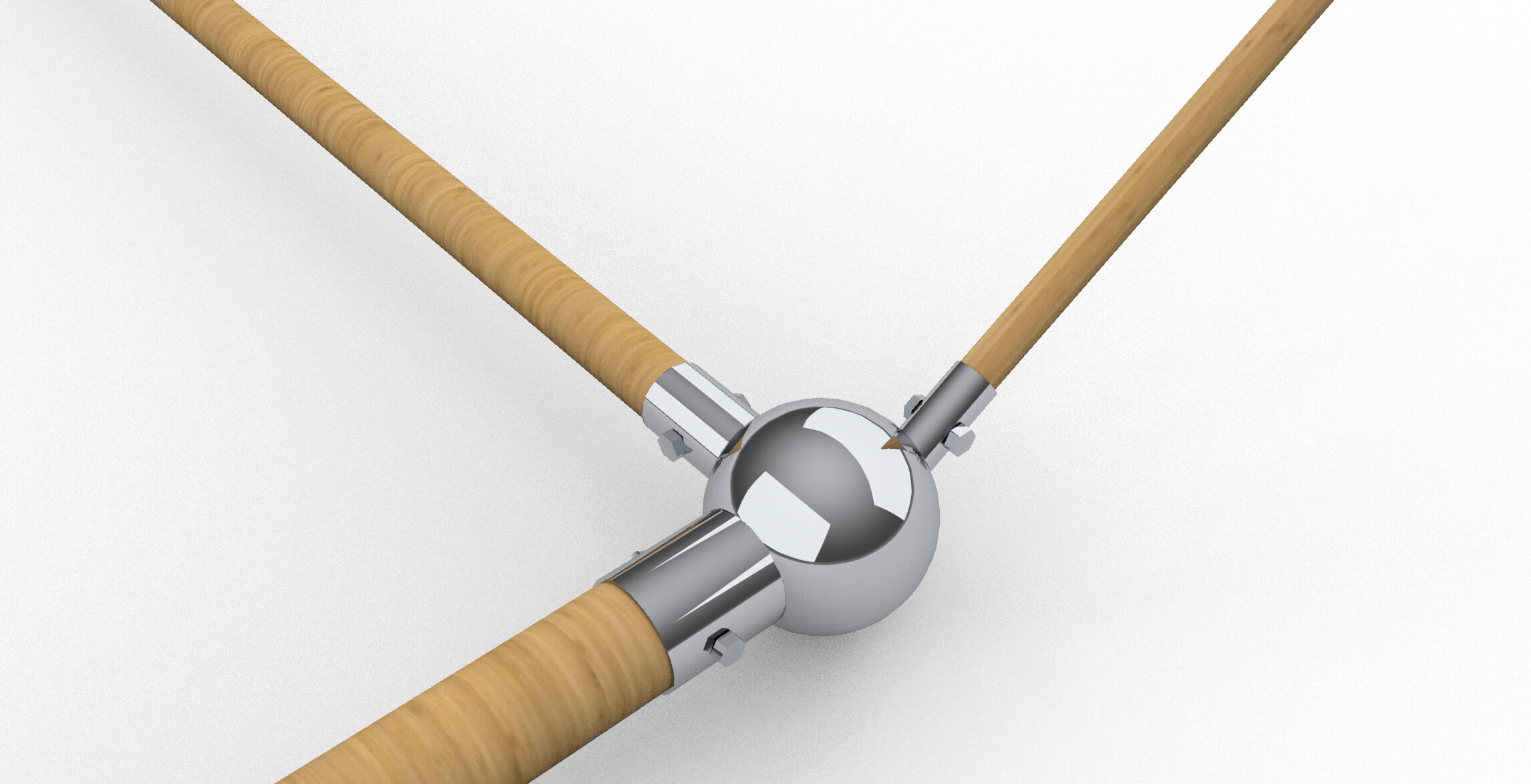

Connection Details

One of the most important / challenging aspects of space frame structures is how the members connect. I decided to explore two potential connection designs that would work for both the columns and the space frame members

Final Product

+

Future Investigation

Below are renders of the final product. Furthermore I had the opportunity to present this project to a panel of engineers and architects, and some areas that I could investigate to further develop this design are

Creating a moment creation between collumn and space frame

Investigating more eco friendly joint options: fiber strips, concrete, bamboo - bamboo joinery, 3D printed joints, wood spheres.

Consider torsional failure.

Consider a closed roof design, with proper water draining.

Consider shape optimization for the overall profile, this could suggest a new profile with a belly on the edges and an arch in the center.

Consider optimizing the truss design for longer members reduce number of joints and make structure easier to construct.