A Building Made Of Dirt

This project seeks to challenge the complex issue of informal settlements and the associated health issues by proposing a low cost eco friendly building solution made of compressed earth blocks

In Fall 2019, I took a class called Intro to Civil & Environmental Engineering I, and as a semester long project students were given the assignment of researching any civil and environmental engineering problem we were most concerned with and proposing a solution. Then we were expected to prototype one aspect of our prosed solution

My group and I decided to take on the challenge of providing eco friendly, low cost housing solutions for the emerging world, in particular - Lusaka, Zambia - in an effort to tackle informal settlements and the challenges associated with them.

Project Members

Nebyu Haile

Laura Chen

Claire Holley

Natasha Stamler

Programs + Tools used

Instron Machine

Excel

Compression Test Machine

Revit

The Problem + The Solution

Interest

There were so many problems we could address. However, my group and I all shared one familiar feeling; we wanted to accomplish two things with our project: helping address the climate problem & helping poverty struck individuals. It is this shared interest that helped us conclude that the topic we wanted to address was informal settlements in Lusaka, Zambia. We decided on addressing this problem because solving it would help thousands of people in need and help the environment at the same time. This specific project was also compelling because it was a problem that had roots in all aspects of civil engineering: civil, environmental, and urban planning.

Photo By - Francis Maingaila

Research

Before proposing a solution my team and I researched Lusaka’s informal settlement issue in depth, we each looked into specific topics:

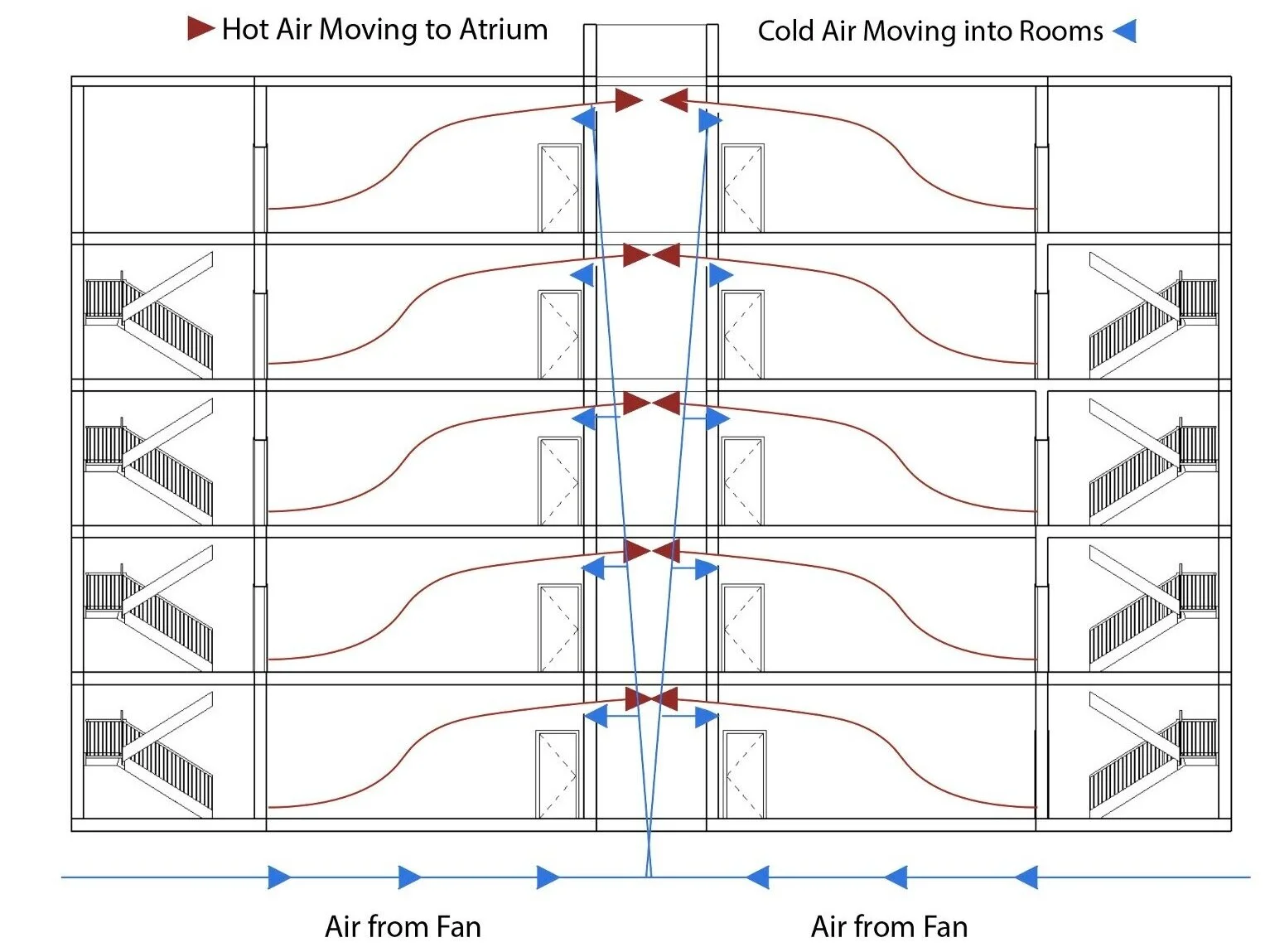

Nebyu - Cooling of informal settlements and associated health concerns

Laura - Hygiene and health issues associated with informal settlement living

Claire - Cost of housing construction and land development in Lusaka

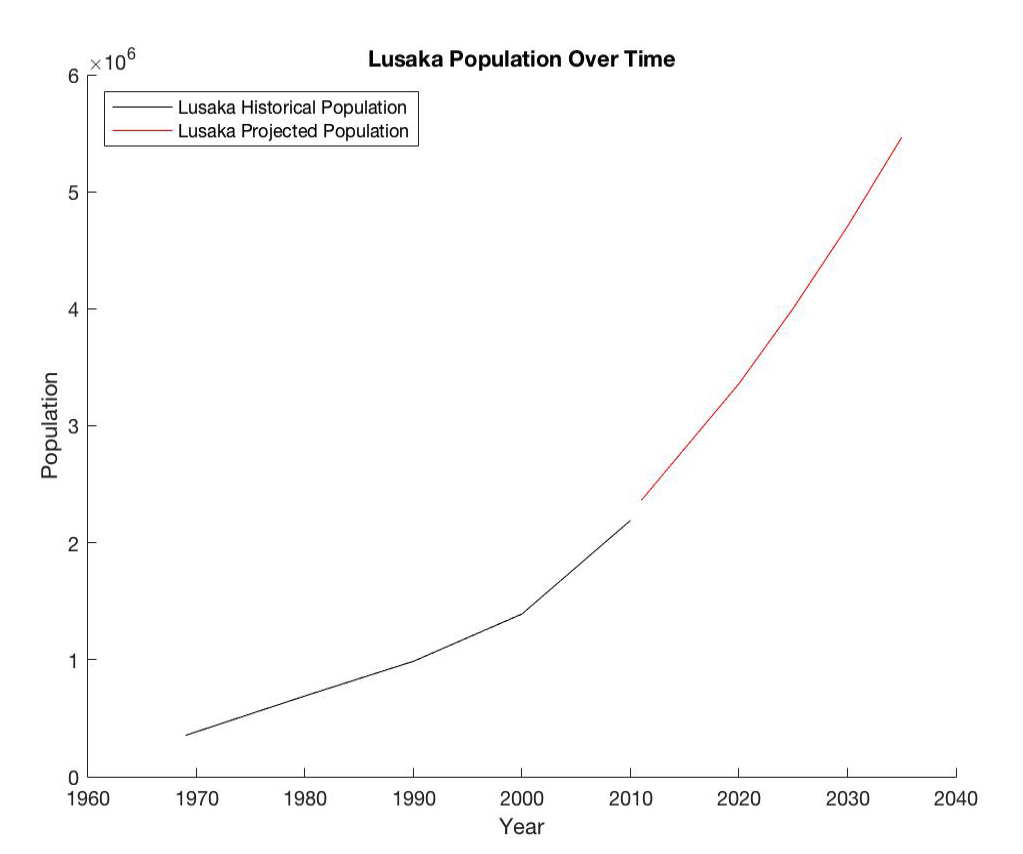

Natasha - Population growth and associated housing demands and challenges.

Findings

Research showed that Lusaka's population is growing, and it's growing fast. In fact, in the next decade, it is estimated to reach five million. Population growth is typically good, but the problem is that 80 percent of Lusaka's residents live below the poverty line, and 90 percent of them live in informal settlements. The problem is that these informal settlements give rise to a plethora of Issues. Some of the significant issues being rampant malaria and cholera, no formal restrooms leading to hygiene problems, and unsafe, unsustainable (no temperature regulation) building design indicates that these residents need adequate housing. In light, if these facts, it was clear that to fix informal settlements in Lusaka and the various health risks associated with them, we needed to find a way to house the 90% of people who cannot afford to live in formal housing.

One of the largest informal settlements in Lusaka - Community Organization Resource Centre

Our Solution

Details of the design can be found in the final paper

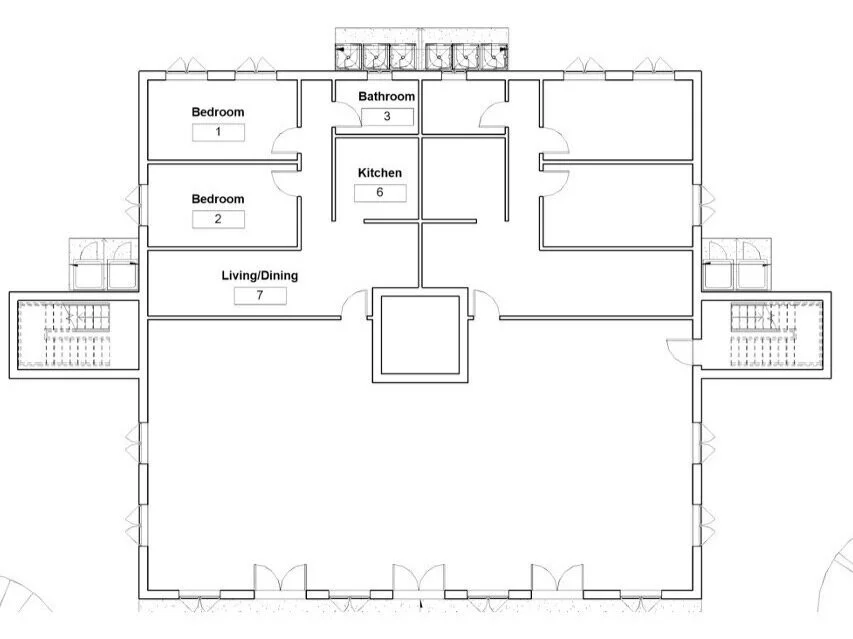

With all these things in mind, we proposed that the solution to fixing Lusaka's informal housing crisis was creating a masterplan for the city that would put multiple square blocks of eco-friendly and affordable five-story apartment units. The buildings made from earth bricks (bricks made from compressing soil with small amounts of cement) have passive cooling to save energy costs, use eco-friendly window filters to stop bugs from spreading disease, and provide proper restrooms for occupants. I was responsible for the passive cooling design, general building design, and renders.

The reason that we felt that this proposed apartment was the best of both worlds is that it provided numerous benefits to the government, so it would make it worth subsidizing the cost for tenants. For example, by moving informal settlers into vertical buildings instead of being spread out, taking up land, the city of Lusaka can gain back valuable land for agriculture or commerce. Another great example is that the construction of these buildings will be locally sourced, and the labor could be provided by the tenants of the informal settlers giving them income and raise the cities economy. The move to formal housing would reduce the deaths and illness caused by poor sanitation. Last but not least, the building is constructed from sustainable and locally sourced materials that help the environment and keeps costs down.

Prototyping The Earth Blocks

The Goal

The use of compressed earth blocks was arguably the most compelling feature of our proposed design as it not only helps tackle the huge environmental damage caused by the use of cement, but it also keeps costs down. What we wanted from the prototype of the compressed earth blocks was to find out if the blocks were strong enough to be used as structural elements in a building as we had proposed.

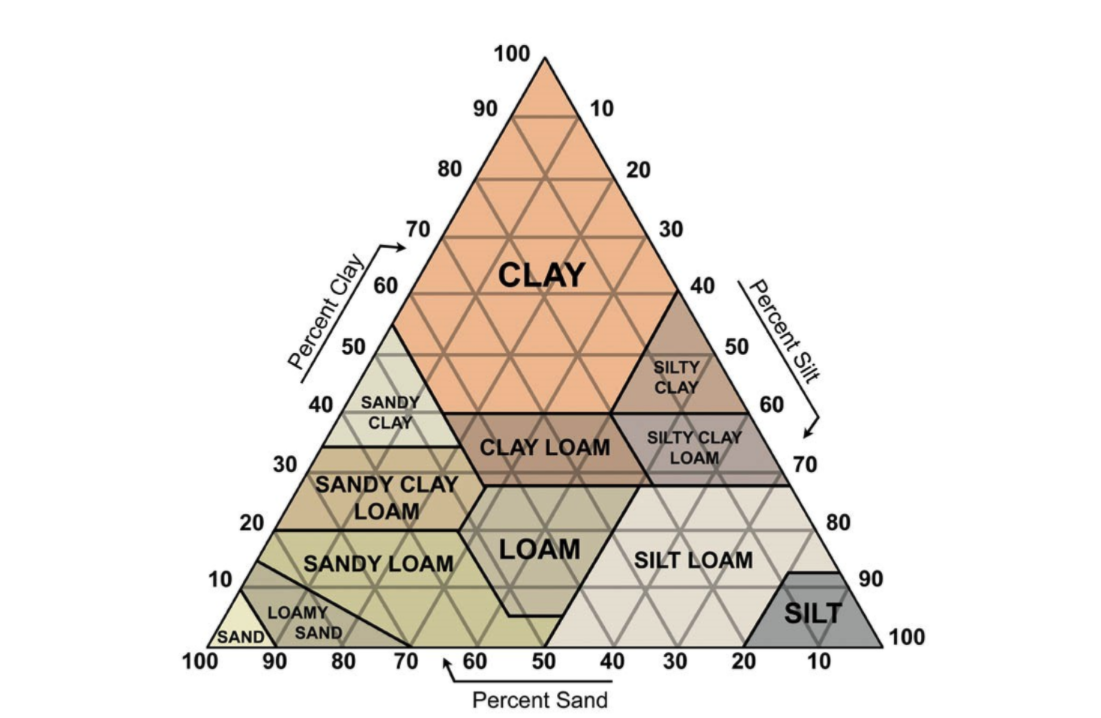

The Mix

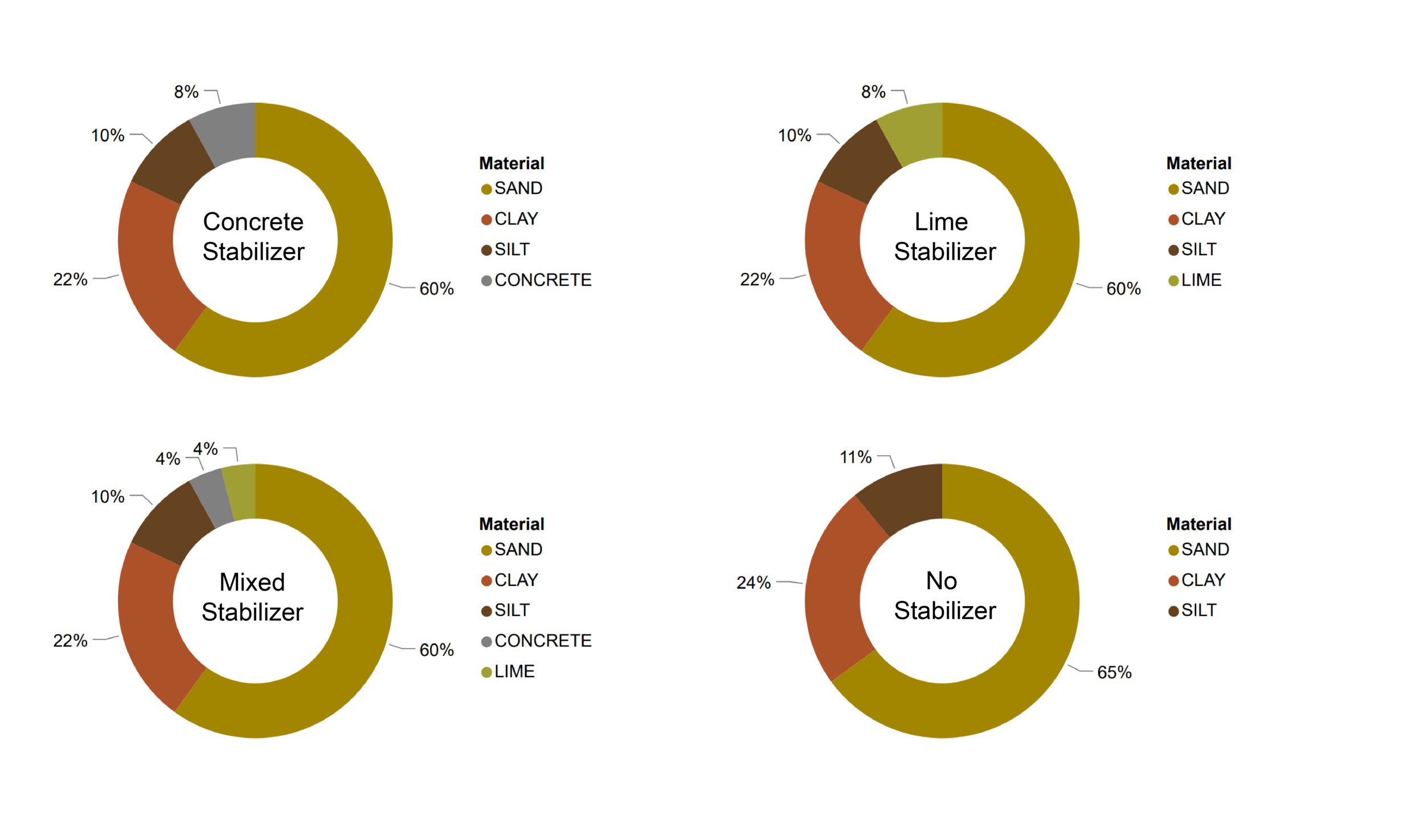

Arguably the most important part of the prototype was determining the composition of our earth block. Our goal was to replicate Lusaka’s soil as best possible. In order to do this we used a soil chart and found references online about the soil in the region. We tried 4 different mixes one with cement stabilizer, one with lime stabilizer, one with lime - cement stabilizer, and one with no stabilizer.

I was responsible with introducing the idea of and utilizing the soil triangle.

Making The Samples

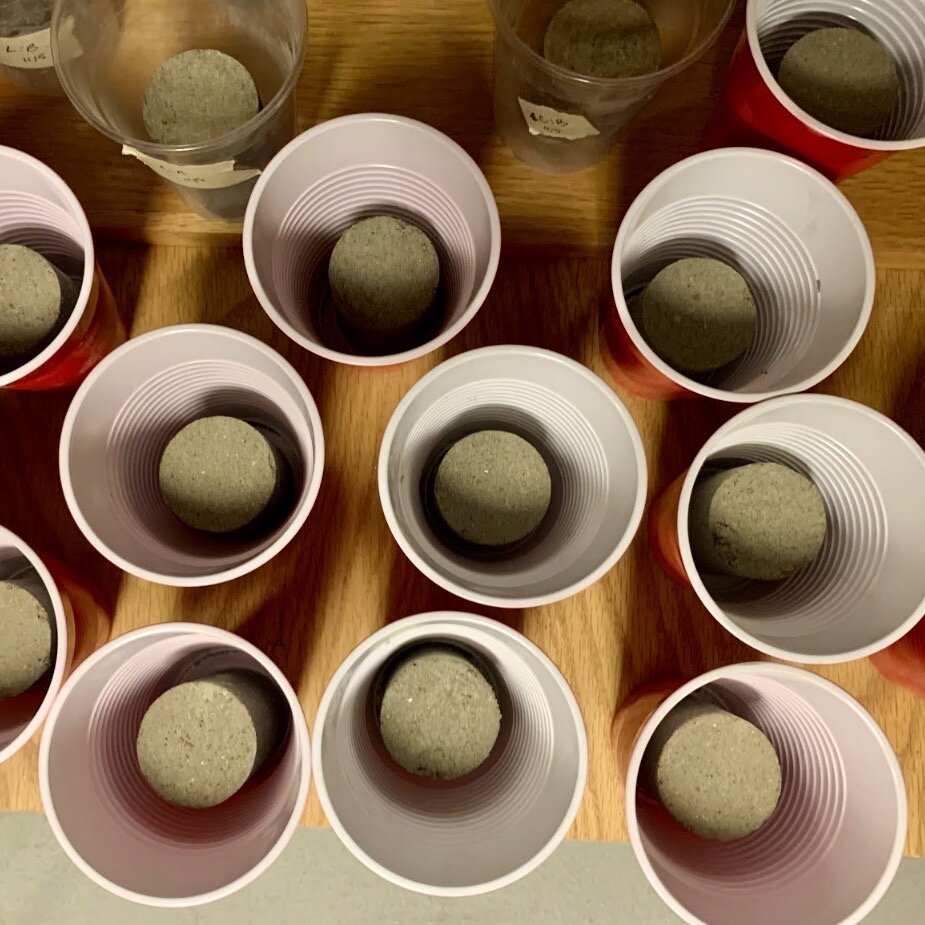

With the mixes determined, we made the “blocks”, in reality we made cylinders in 2:1 ration of height to width. The reason being that for experimental testing of strength there was no need to make actual rectangular blocks which would have consumed much more material. We made 6 of each block for 24 total blocks.

The blocks were made by first creating the mix then putting it mix in a custom built mold in which we then took to a Instron machine where we compressed each blocks over 5 minute period with a max load of 25 kN. Once done they were left to cure for 28 days.

As an experiment we tried adding fiber to a block because fibers potential increase strength, but the fibers ended up clumping and causing break so we stopped that idea there.

Testing The Blocks

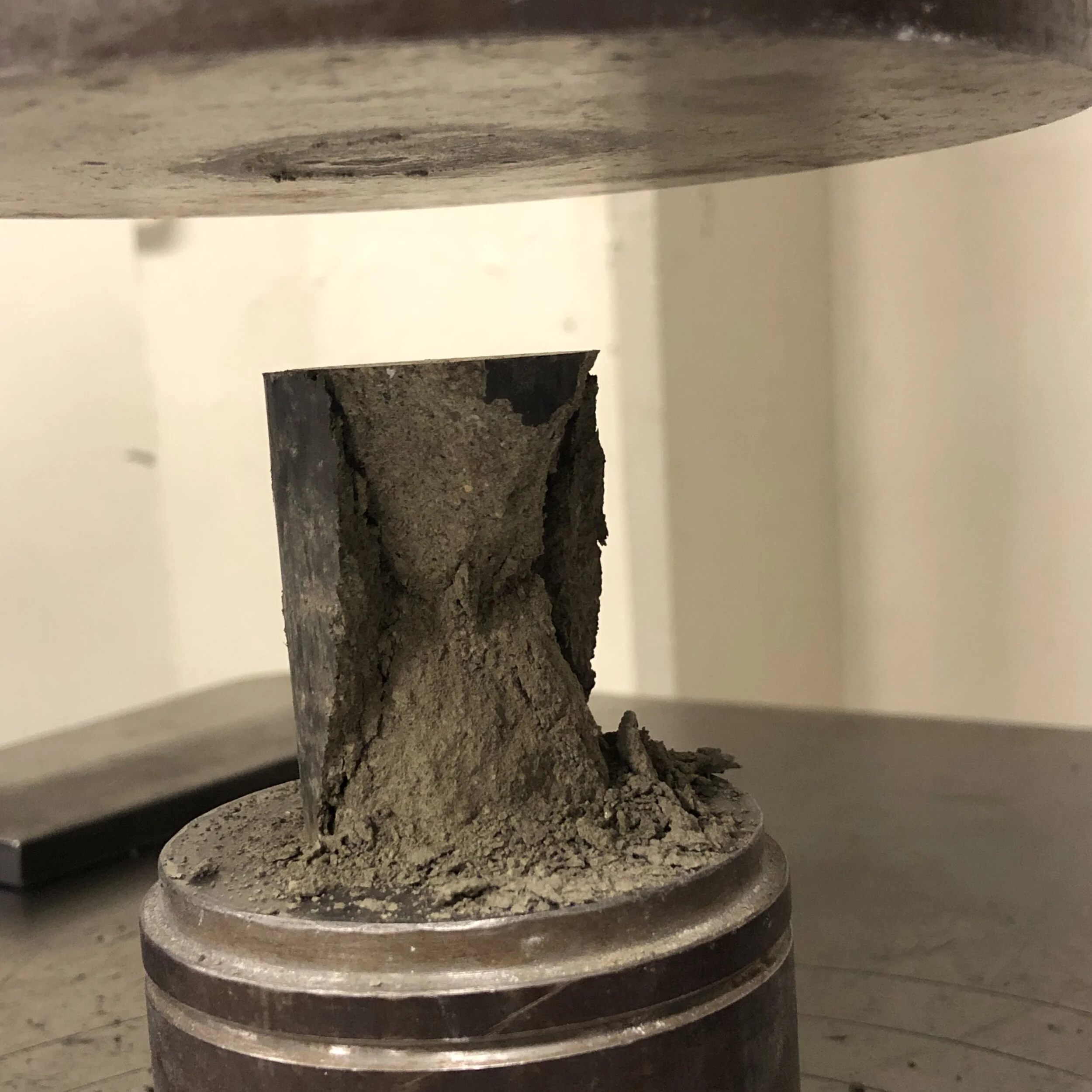

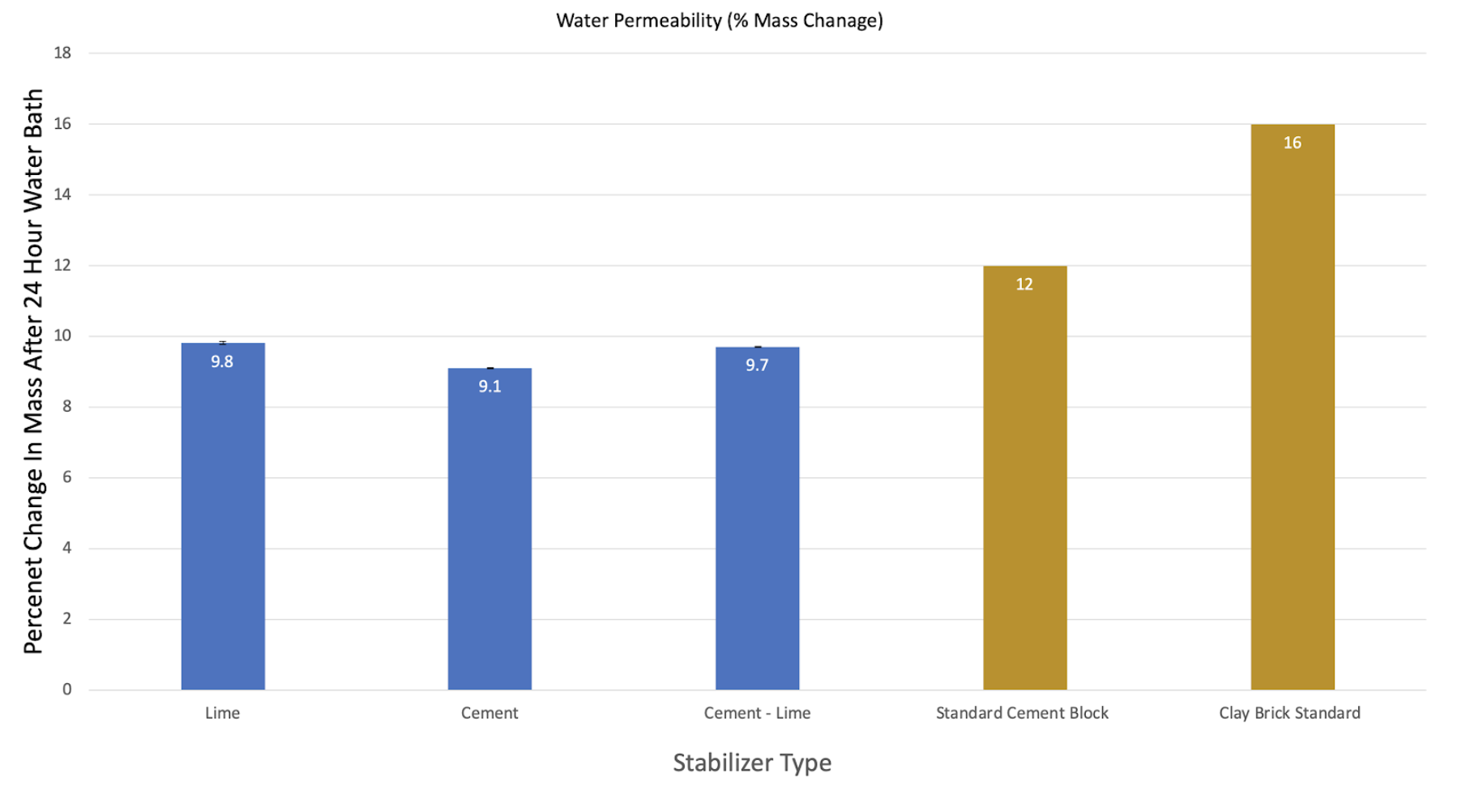

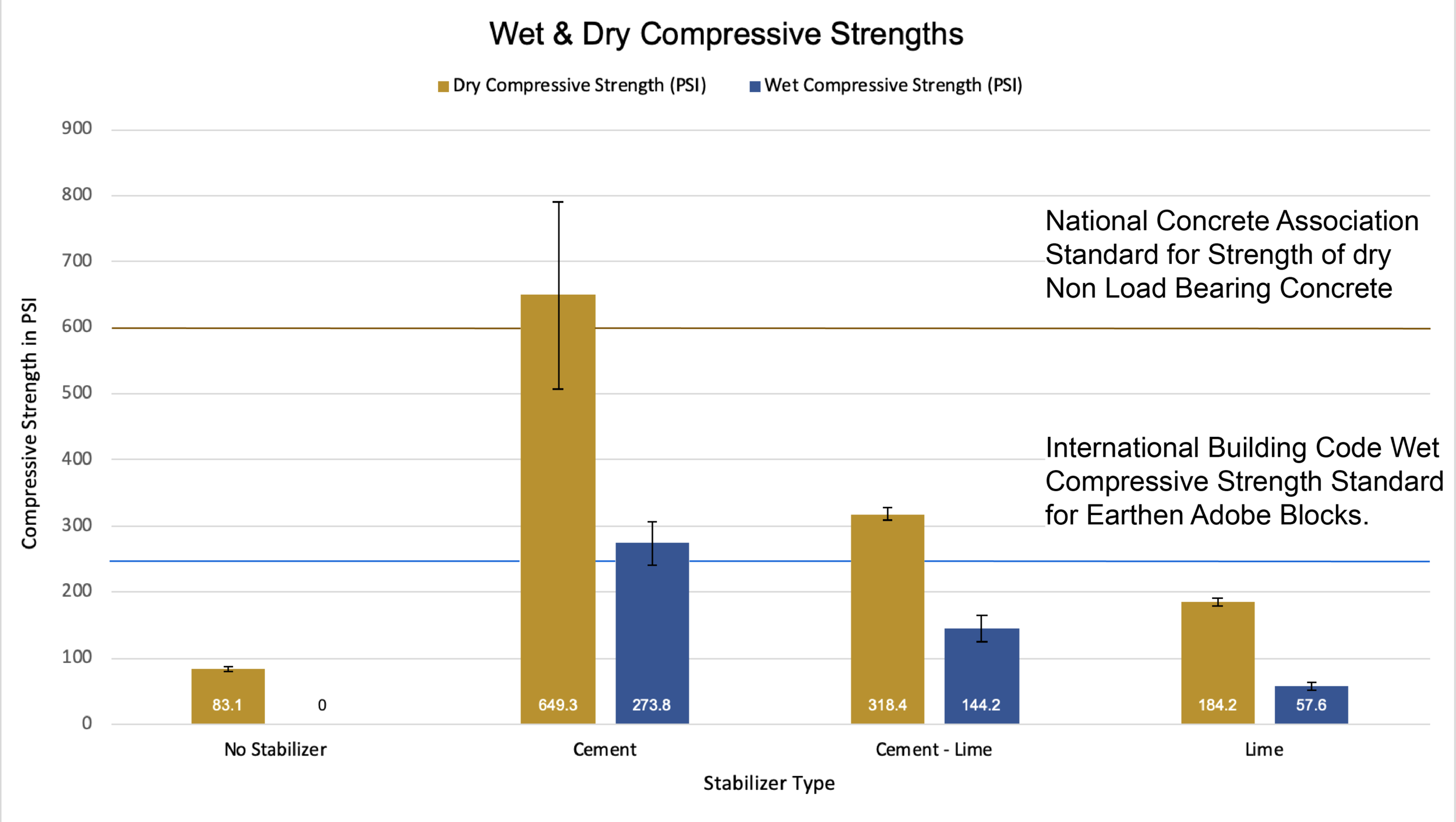

Once the 28 days were up we tested all 24 blocks. For each of the four mix types, there were 6 blocks - on 3 of them we conducted a wet compressive strength test by first submerging the blocks in water for 24 hours then immediately cursing them and on the other 3 we did a dry compressive strength test.

Results

+

Analysis

In the end none of the blocks were strong enough to be load bearing structural elements; however, the cement stabilizer mix was strong enough to be a non load bearing element which was still a very exciting result.

What this meant in regards to our proposed building design is that we could make the design work so long as the building had load bearing columns, which would be concrete, then all the walls could be made of the compressed earth blocks. While this result does mean that we cannot avoid the use of standard concrete columns and beams all-together and our mix still has some amount of cement there is still a significant savings in regards to cost and environmental factors by using the compressed earth blocks.

Based on a rough calculations assuming that in both cases that concrete columns and beams are used our proposed building designed with compressed earth blocks (8% cement in mix) for the walls instead of standard concrete blocks (25% cement in mix) would save nearly 170,000 kg in cement which is a savings of nearly $60,000.