Module + Screen

Module + Screen is a project about how repeated units can come together to form an intricate screen that manipulates light.

In Spring 2020, I took 4.021 which is MIT’s introduction design studio, and for our second assignment “Module + Screen”, students were tasked with creating a “module” using styrofoam that could be repeated to create a screen. The focus of the “module” was to test the limits of styrofoam, and the focus of the screen portion was to test how the screen could be designed to interact with light.

Project Members

Nebyu Haile

Programs + Tools used

Foam Cutter

Laser Cutter

Rhinoceros 3D

Conception

Although the module part of the assignment came first, I did a lot of thinking about the screen portion of the assignment too from the very start. In regards to the module I took inspiration from a project called “stacking storage” which is a dynamic storage system that could be rearranged into multiple configurations. As for the screens I took inspiration from a project called “Shadow Play” which is a shade structure that is intelligently designed to create shadows at certain areas based off the suns location at different times of the day. Lastly I took inspiration by a building called MuCEM which has a facade that is in essence one large screen.

MuCEM - Rudy Ricciotti

Shadow Play - Howeler + Yoon Architecture

Stacking Storage - Paul Pettigrew

Designing The Module

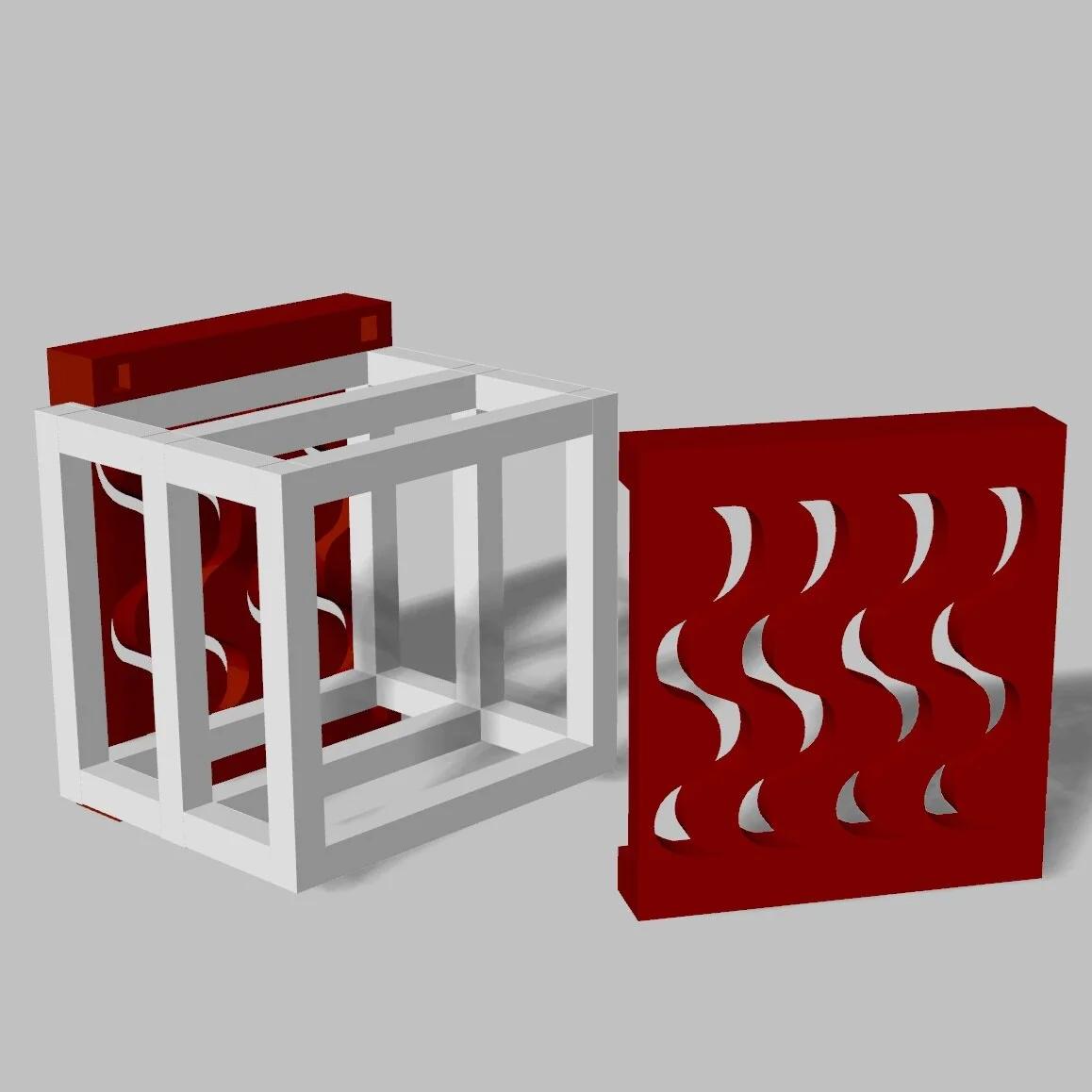

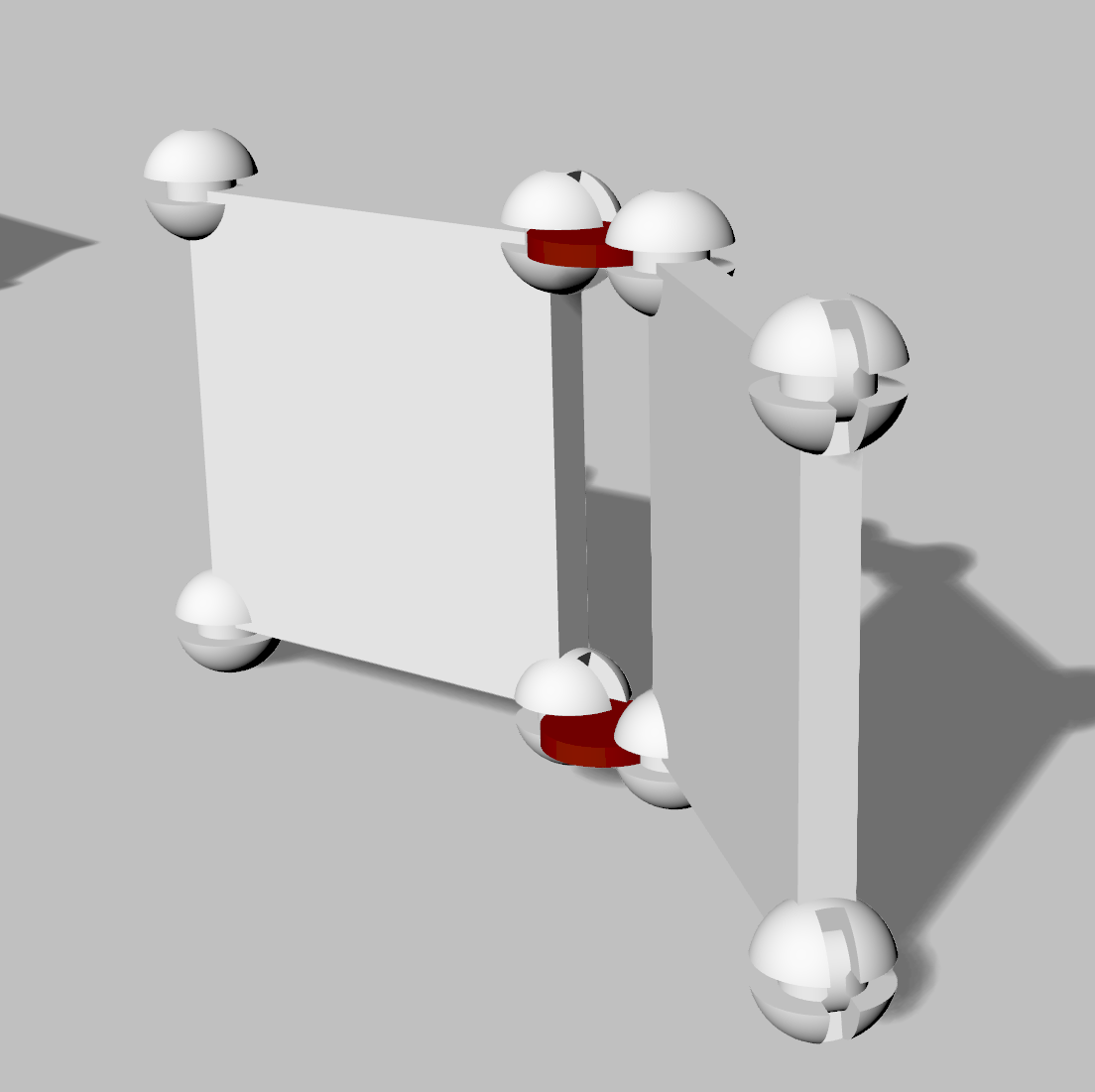

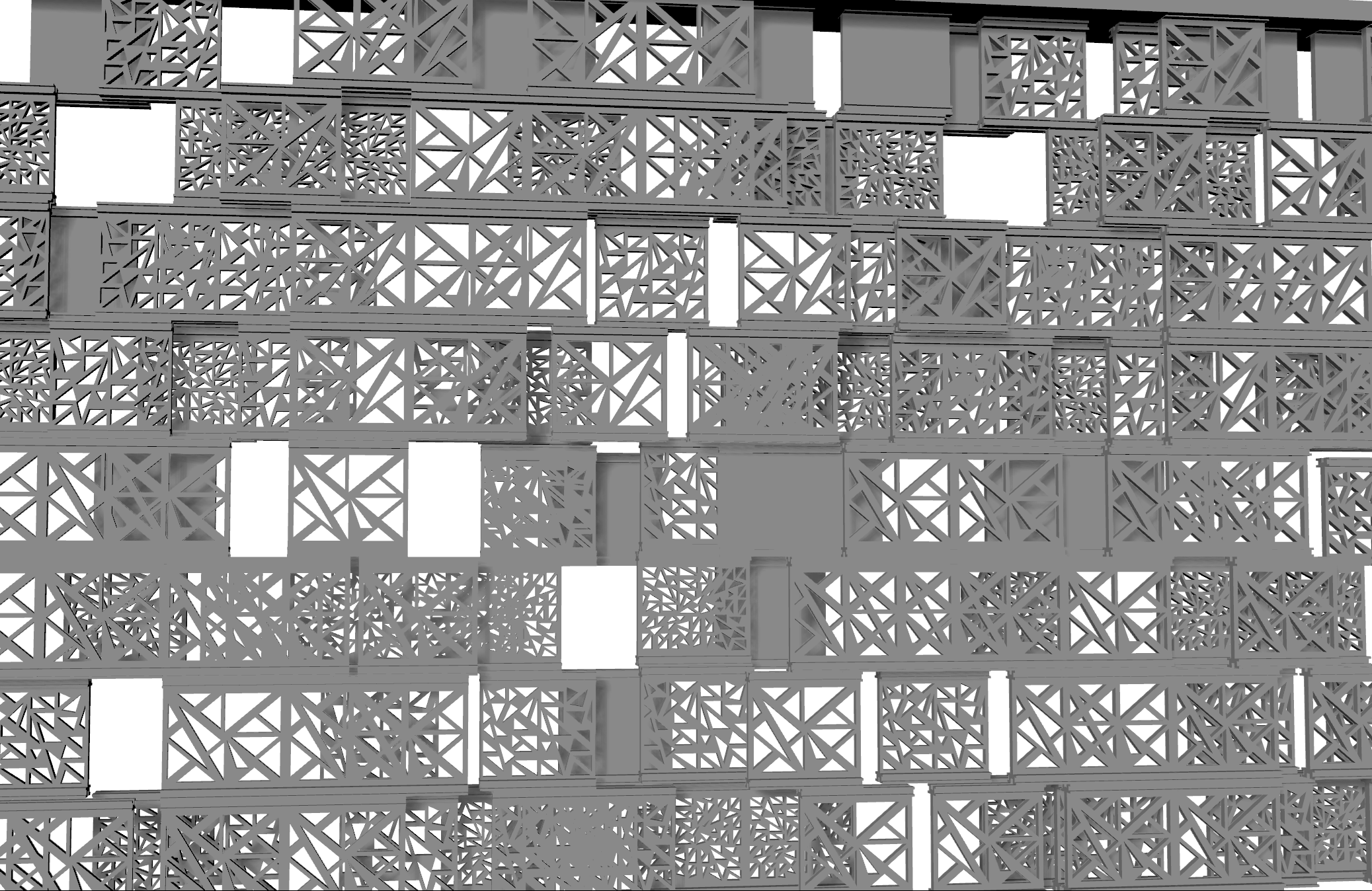

The basis of my module was three small and thin rectangular square with slits cut into it that would create patterns when light passed through it. Furthermore, taking inspiration from Stacking Storage, I attempted to make my module reconfigurable by exploring various connection systems for the three squares including a rack system, a pin system, and a sliding and slit system.

Ultimately I decided on iteration three which had the three rectangular squares with three different patterns and a sliding connection mechanics. I liked this design the most because it gave the user a lot more control of how light passes through the module and later on screen. I was inspired by the idea of control form “Shadow Play” because I liked thinking of the module as a tool to control light rather than simply an artistic shadow making unit. By having a sliding connection the three squares could slide in front and behind one-another allowing the user to control the pattern density and hence light that passes through.

Iteration 1 - Rack System

Iteration Two - Pin Connection

Iteration 3 - Sliding Connection

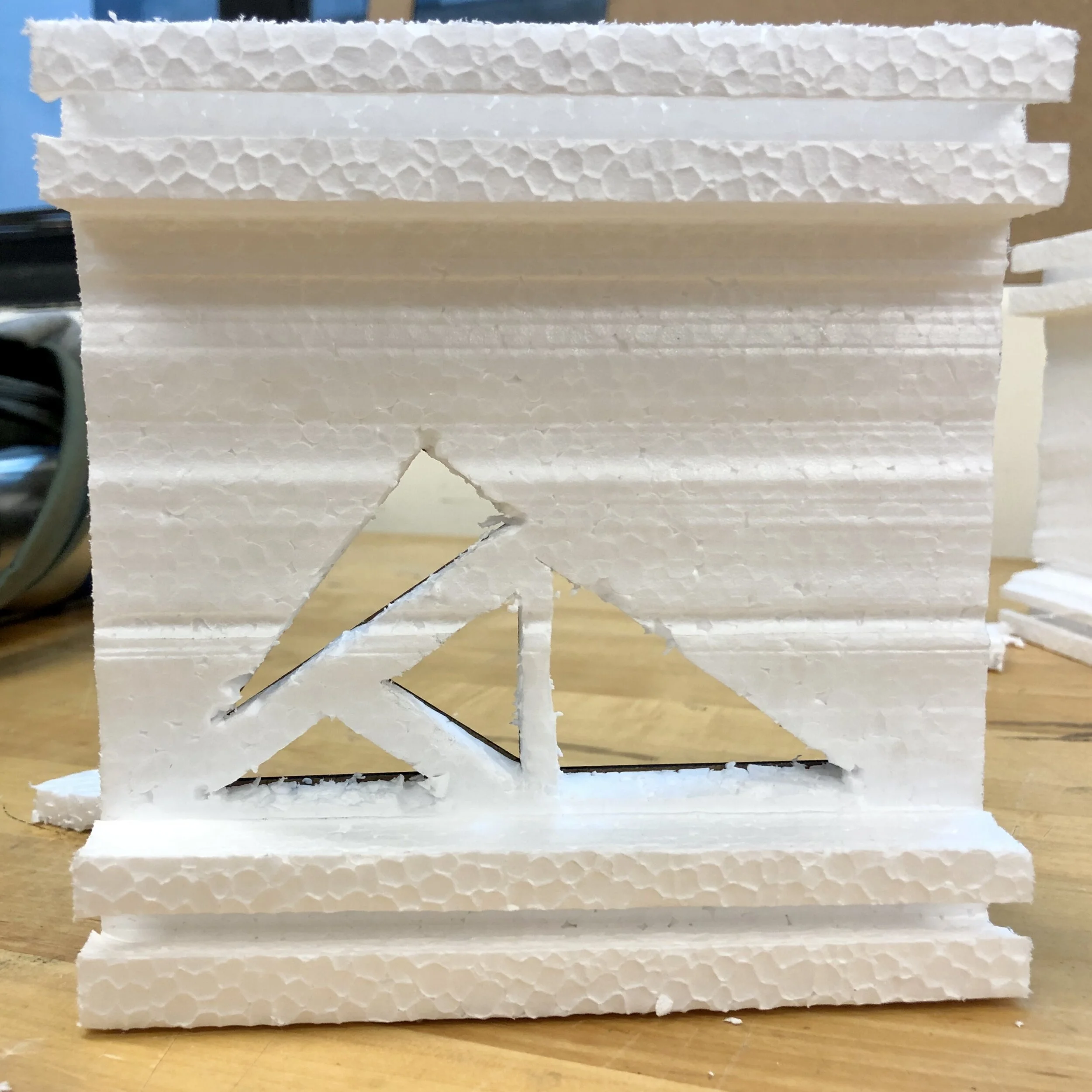

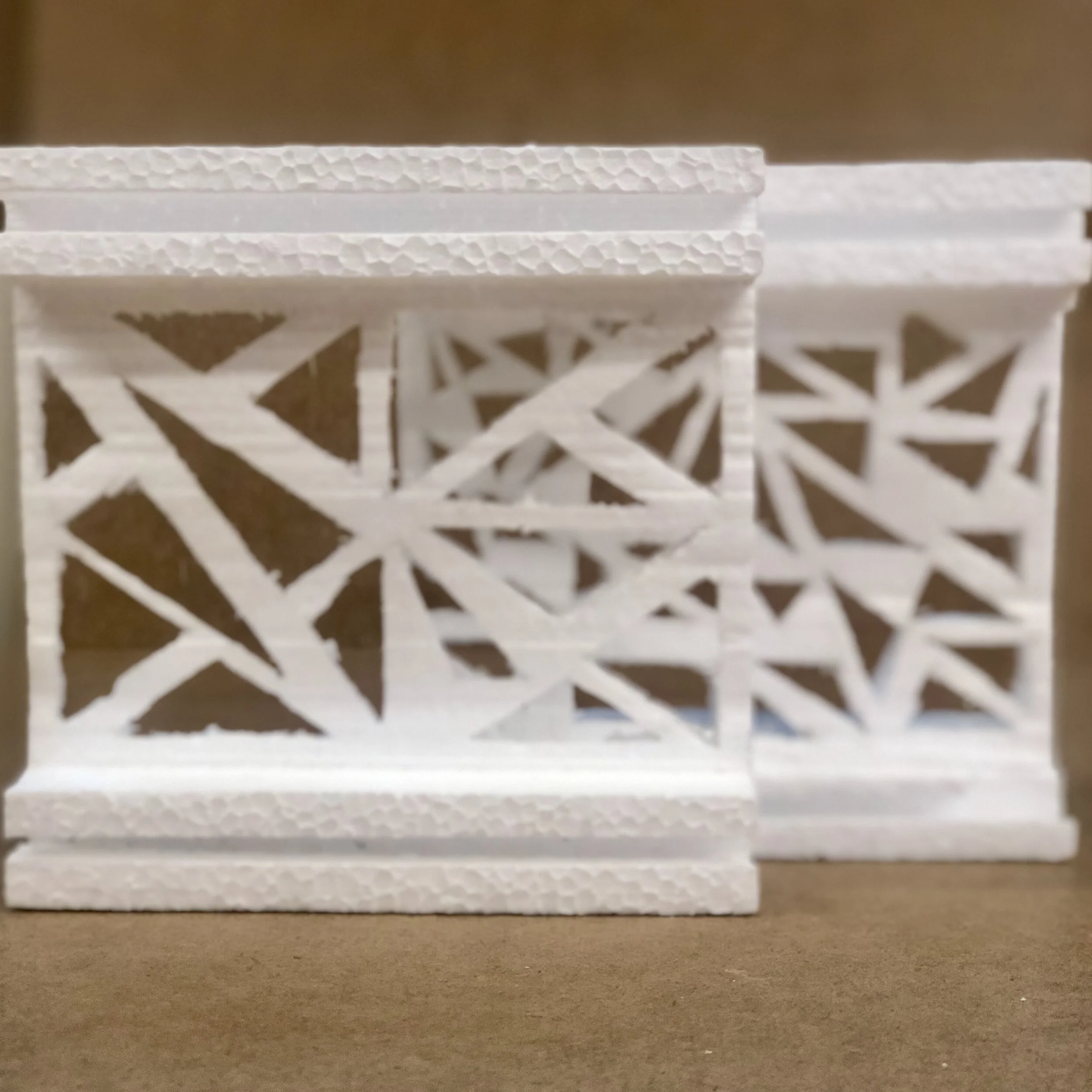

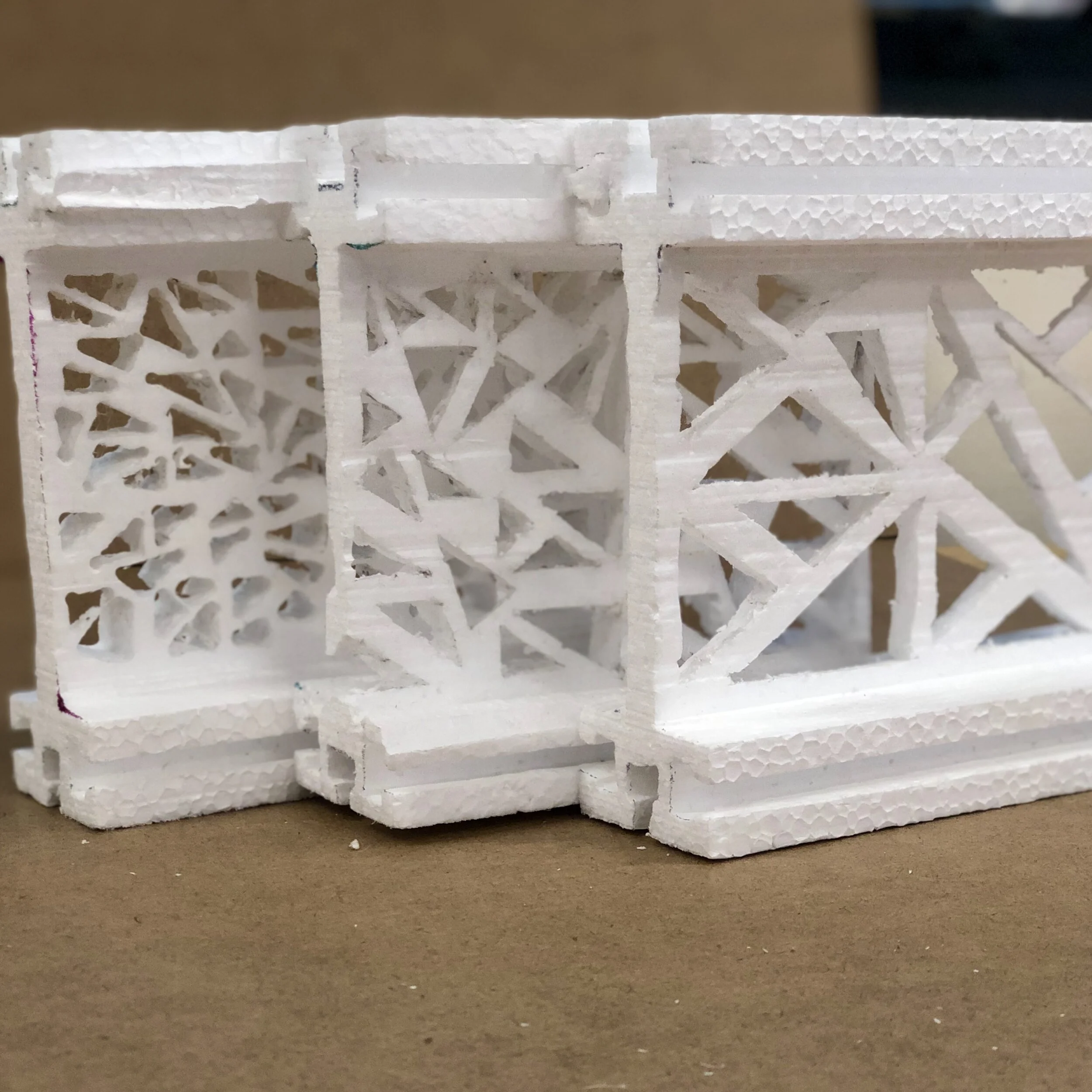

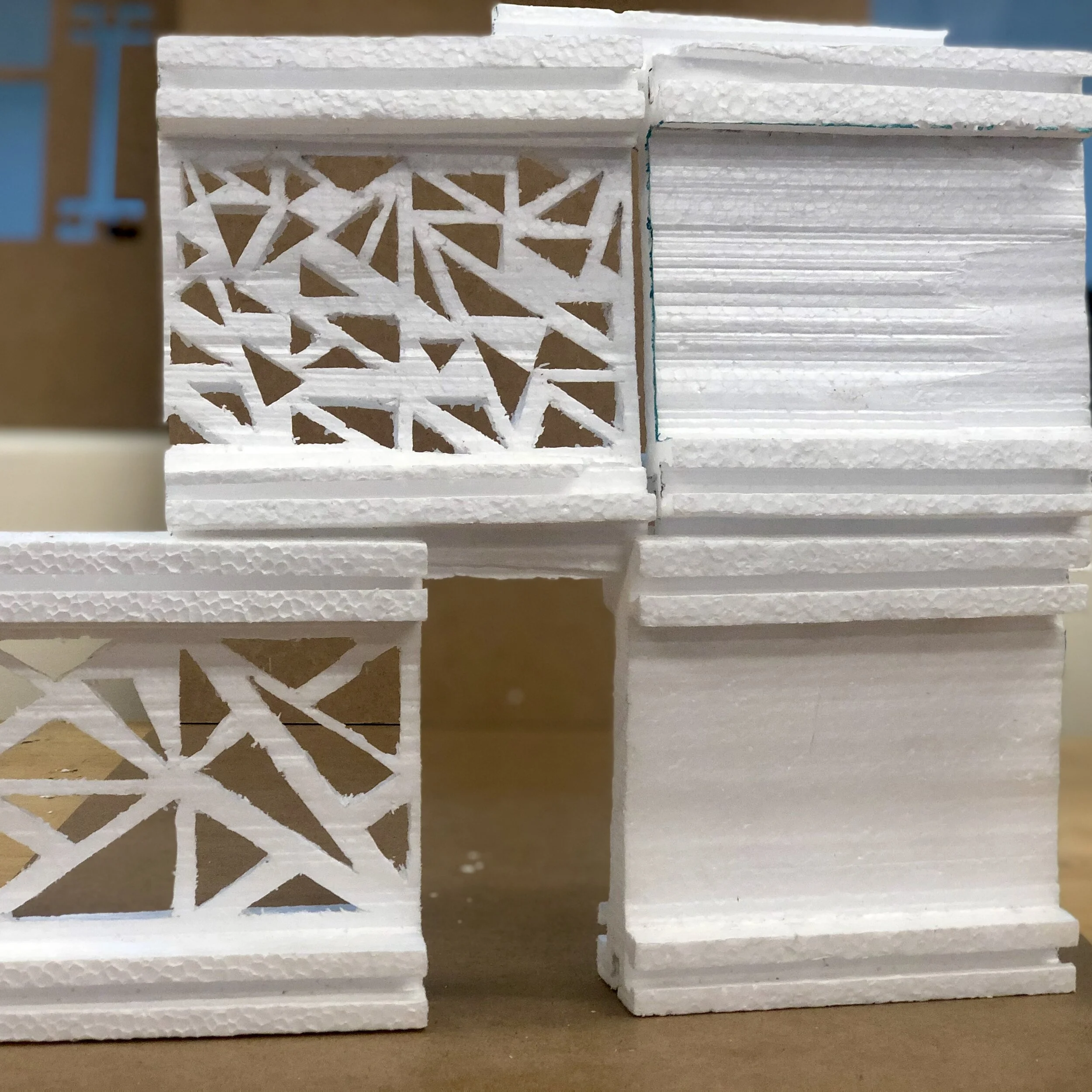

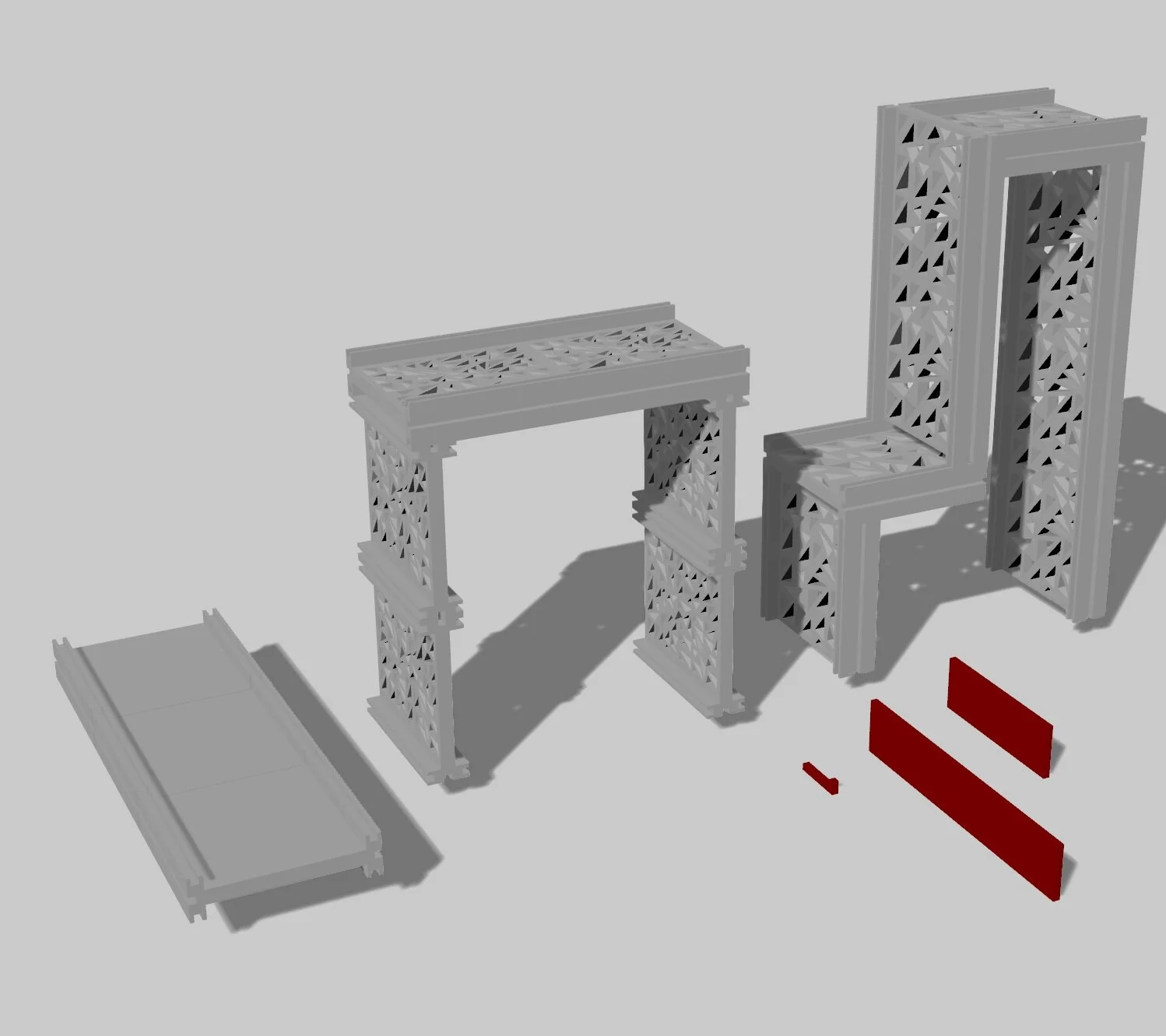

Styrofoam Model

After picking a module design I started creating it in styrofoam. to make it I used a laser cutter to create a chipboard stencil of the module profile and pattern, then used a combination of a foam cutter and exacto knife to cut the styrofoam cube to shape. The images show how the rectangles can slide infront of one another and on top of one another. The fact that the sliding connection worked on a material as delicate as styrofoam was most impressive.

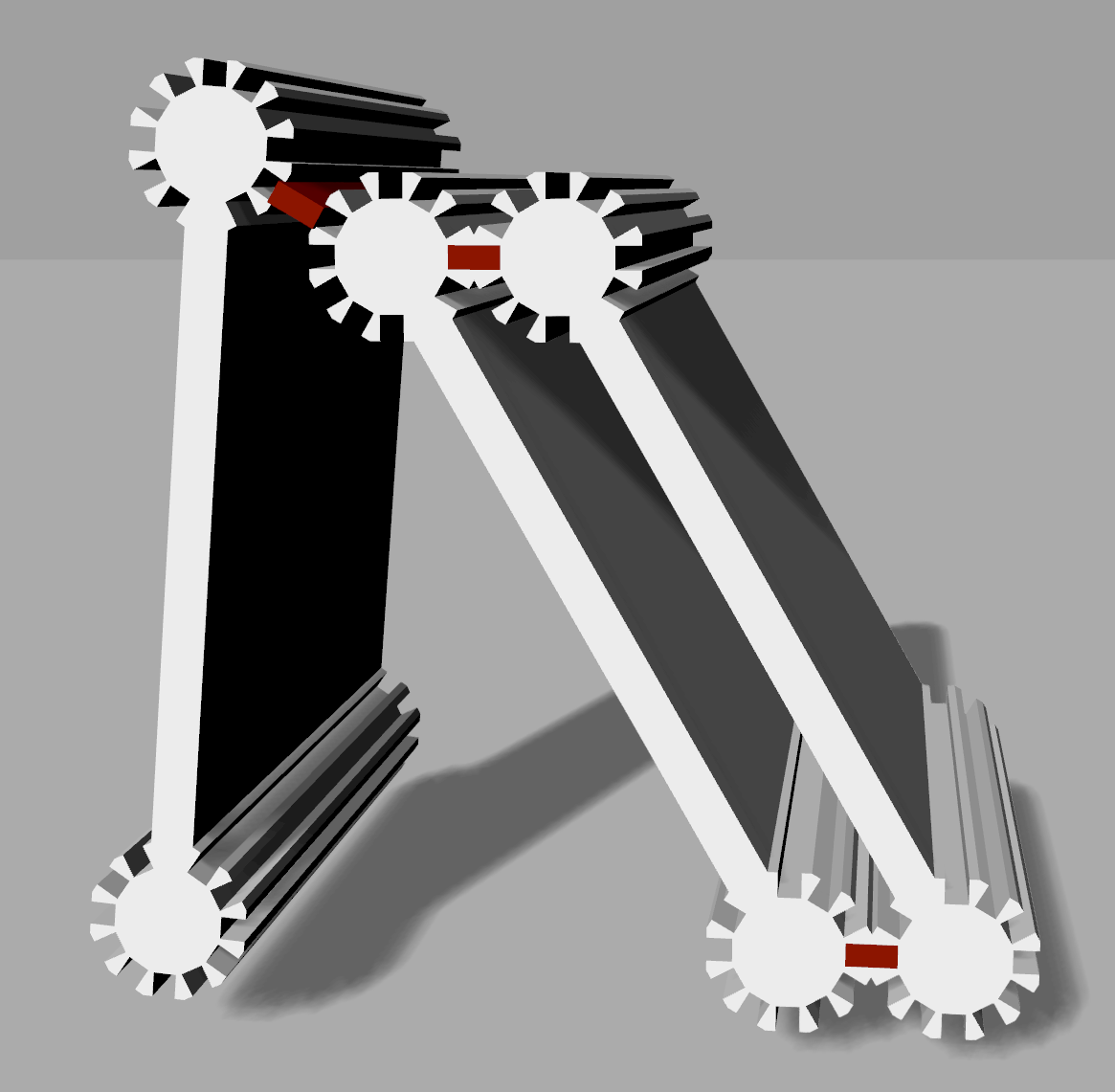

Investigating Alternative Modules

After knowing that the proposed sliding connection was feasible with styrofoam as a material, I explored two more potential modifications to the module. These modifications kept the sliding connection, but tried advancing it to allow more configuration possibilities. In the end I decided to stick with iteration three from before because while promising, the connections I came up with in rhinoceros seemed to complex for styrofoam construction

Making The Screen

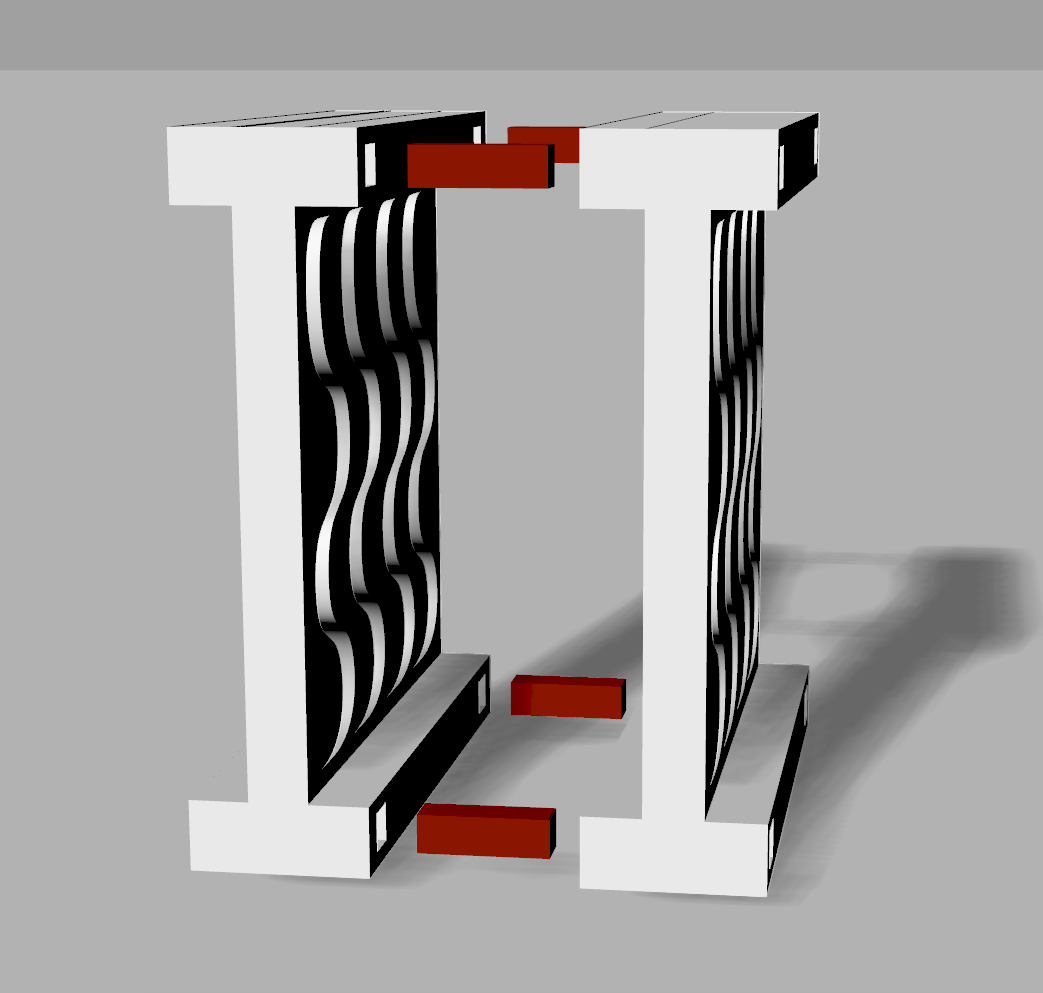

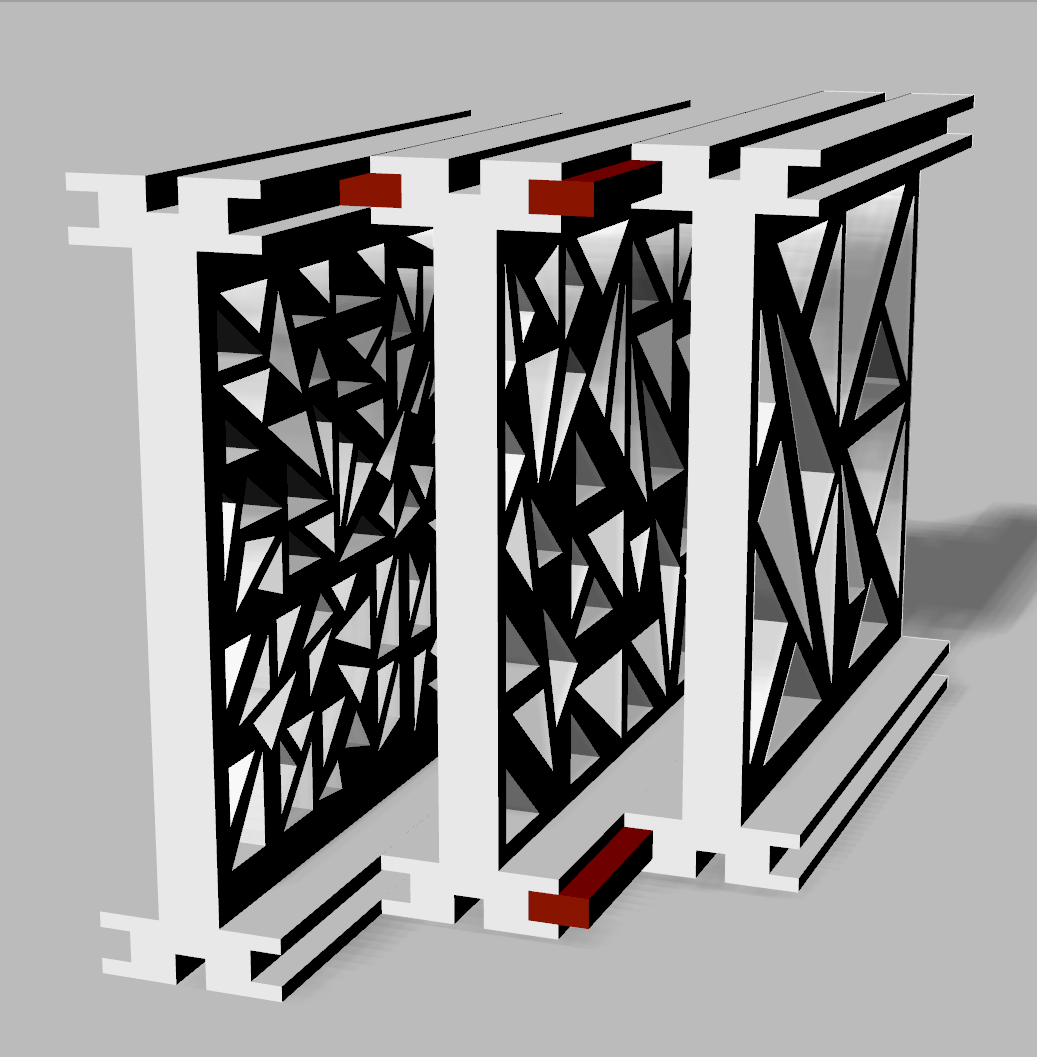

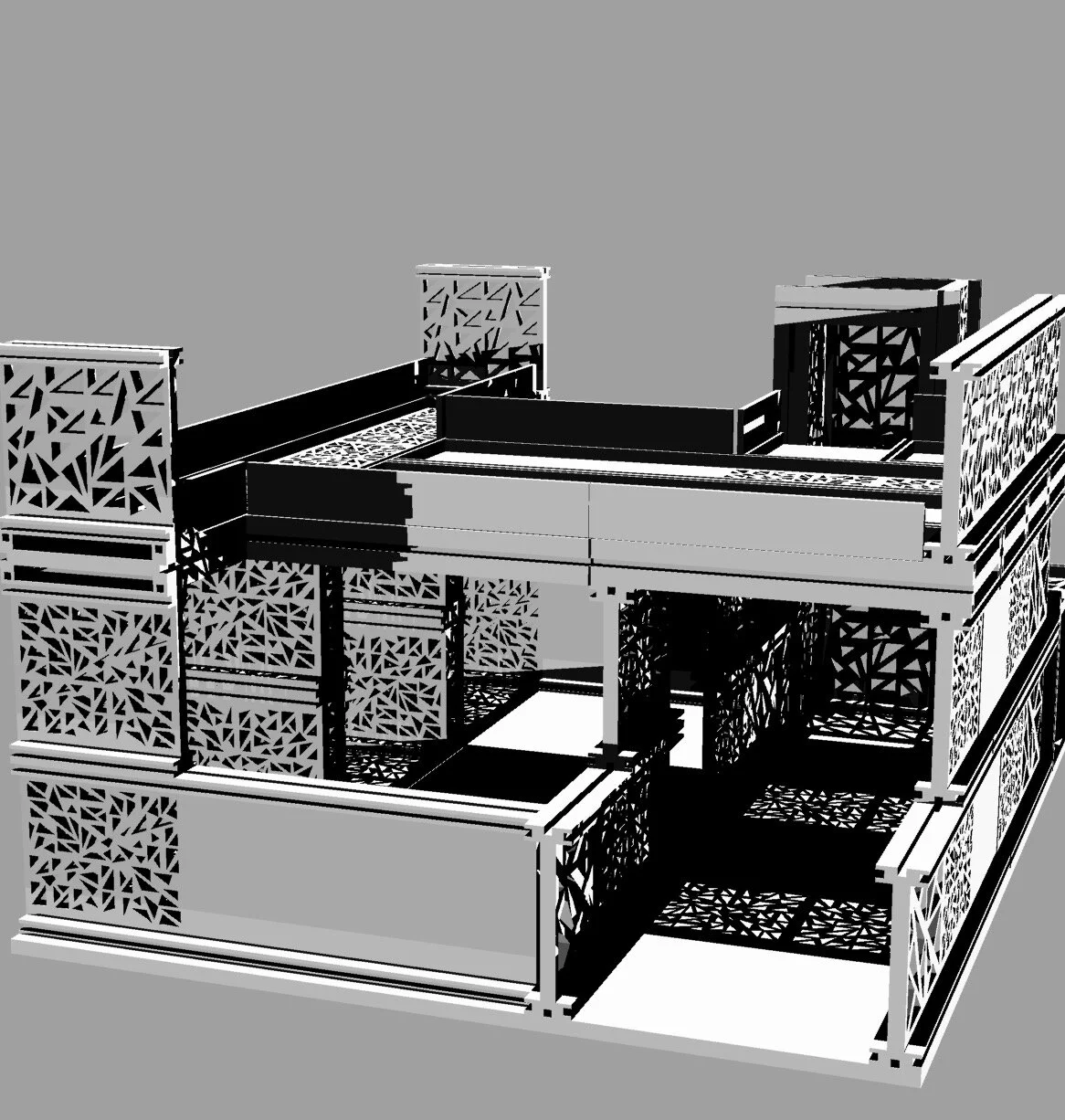

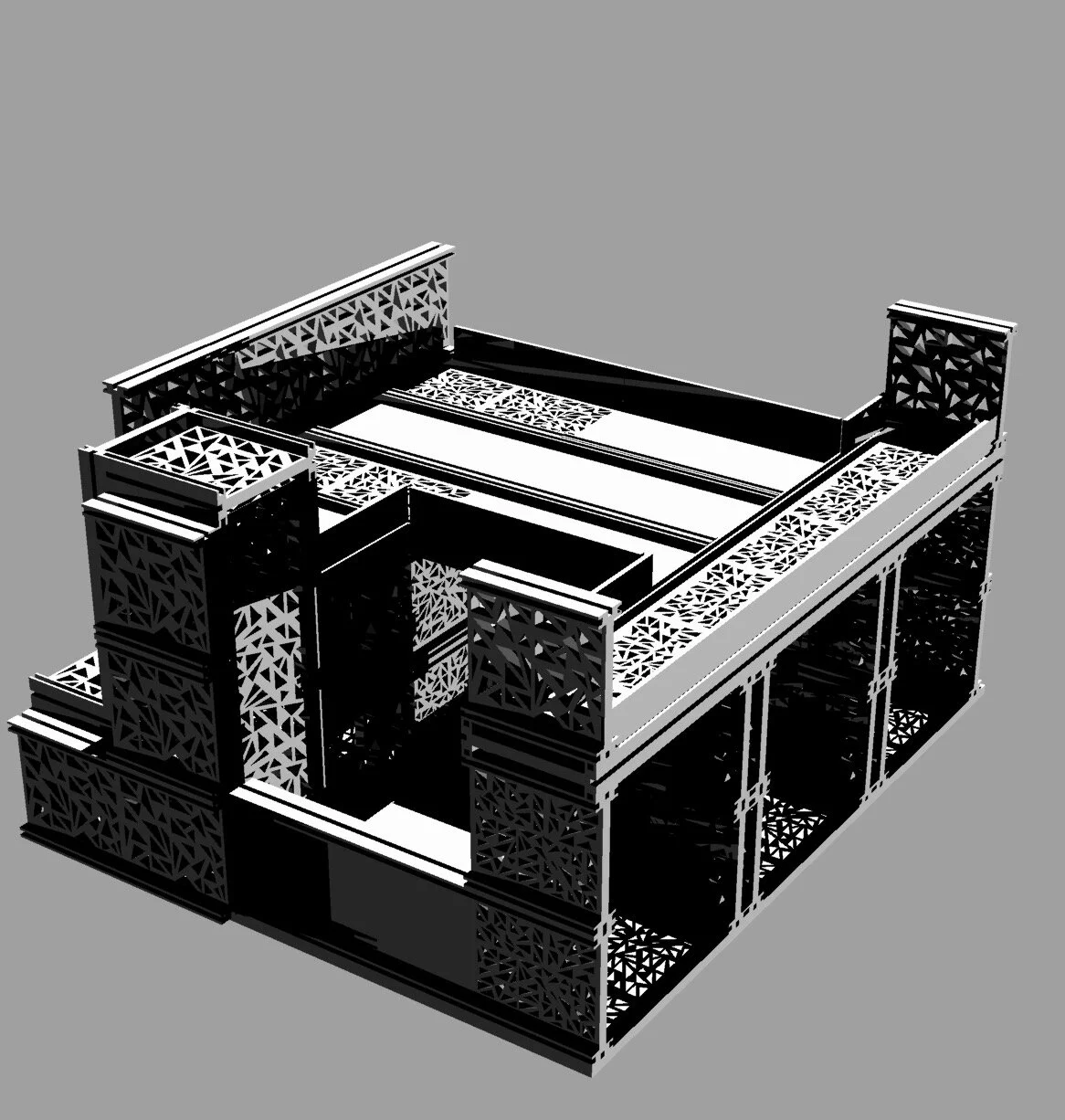

With the module finalized, I then repeated the module units in rhinoceros to create a 3’ x 4’ screen. This screen was supposed to be built with styrofoam, but due to classes moving online the rest of this project was done all on rhinoceros.

The images and video below showcase the power of the reconfigurable module design when it is repeated into a screen. One can imagine having this screen on a glass wall in a house and the user being able to control and manipulate how and where light enters a room.

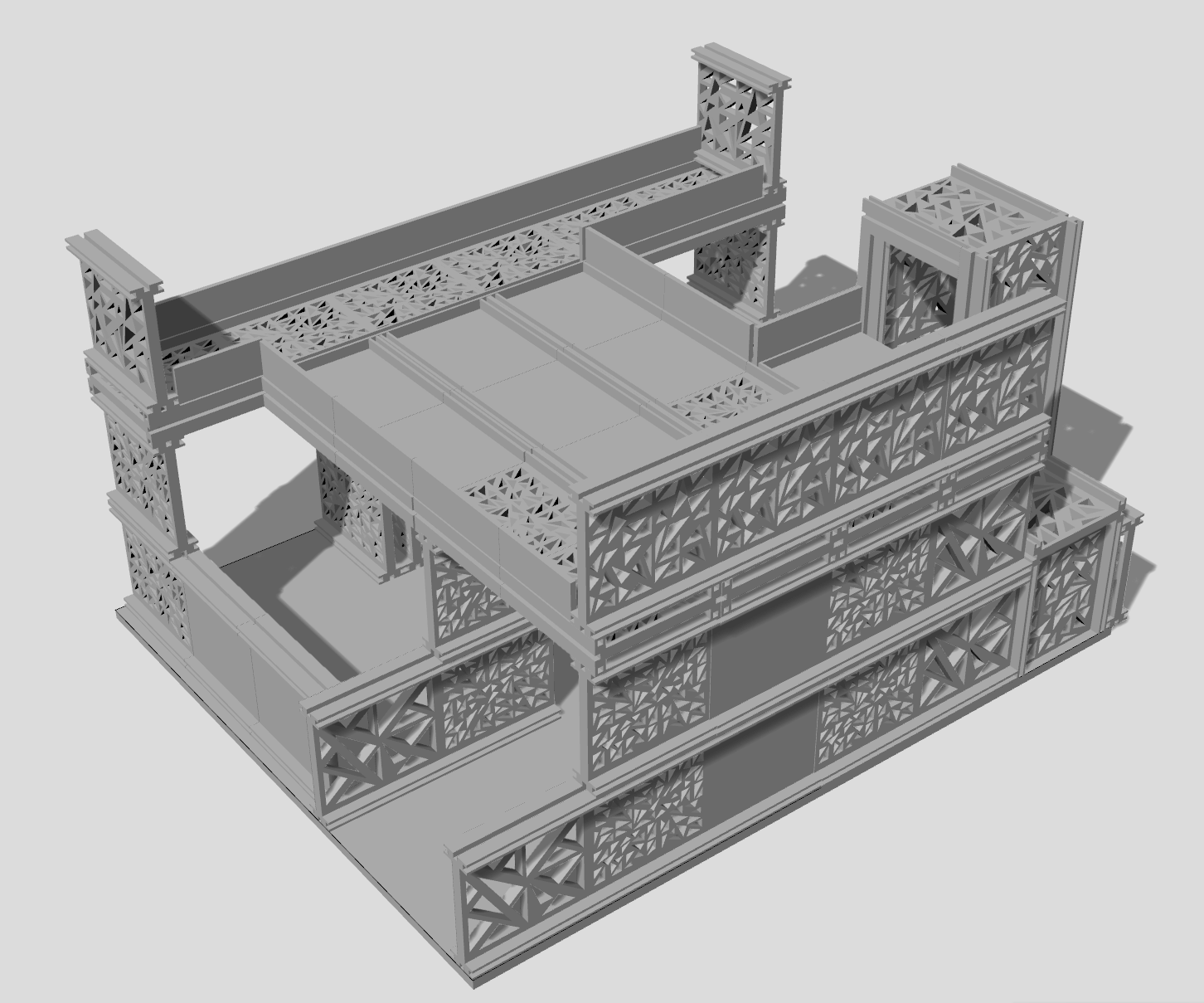

Exploring Architectural Applications

+

Future Investigations

Although not required, inspired by MuCEM, an interesting potential I saw for my screen + module was a potential architectural take on the system. The vision for this was that the term “module” is rather arbitrary, so what if I connect my smaller modules into three-dimensional shapes which would then become my larger modules, and these modules on the scale of a building could come together to form modular buildings which had screens incorporated into their structure. The images below show what some larger modules would look like and the potential buildings that they could come together to form. In taking it to three dimensions I did have to design a new “L” connection shape and new connection sizes.

If I were to investigate this project further, I would want to switch to a sturdier and environmentally conscious material like chipboard or bamboo sheets and experiment with the alternative modules and see what that would mean for the screen and the architectural applications.